Production Machining focuses on helping niche machining businesses become more efficient operations. For our September Technology Showcase, we’re spotlighting products that will be showcased at this fall’s Eastec event, which is set for Oct. 19-21, 2021, at the Eastern States Exposition, in West Springfield, Massachusetts. This preview includes tooling speed increasers, CAD/CAM software for streamlining processes, presetting tools for optimizing machine utilization, a system for automating loading tools, and more.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s August Technology Review.

Click on each link below to read the full product post:

Platinum Tooling Speed Increasers for Boosting Productivity

Photo credit: Platinum Tooling

Platinum Tooling Technologies Inc., the exclusive importer of Heimatec tools, angle heads and multi-spindle heads, has extended its product offering to include the current Citizen tool program. In addition to the standard live and static tools, Platinum Tooling offers 1:4 speed increasers for the most current Citizen machine models.

Mastercam 2022 Designed to Streamline Job Process

CNC Software Inc.’s Mastercam 2022 is said to include features and enhancements to further streamline the job process, from setup to completion. The CAD/CAM software adds the Unified Multiaxis toolpath, 3D High Speed Dynamic OptiRough toolpath and new mesh creation and editing capabilities, including the ability to reconstruct models from scanned data.

Haimer's Tool Presetter for Increased Machine Utilization

Haimer USA’s Microset VIO Linear presetting machine is designed to increase machine utilization. The company says that the Microset tool presetting machine reduces setup times by as much as 70% and enables machinists to increase machine utilization while also streamlining tool setting processes.

Somma Tooling for Automatic Screw Machines, CNC Lathes, Swiss-types

Somma’s range of products includes tooling for automatic screw machines, CNC lathes and Swiss-type CNCs. Somma offers broaching tools and broach toolholders, form and shave tool blanks and a quick-change insert form tool system. It also offers cutting tools, collets, bushings, work holders and box turning tools.

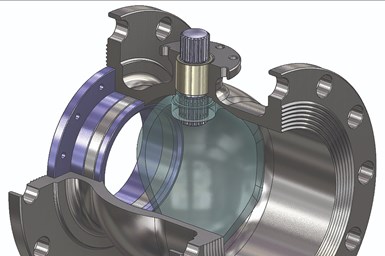

Caron Data Management System Automates Tool Loading

Photo credit: ToolConnect

Caron Engineering’s ToolConnect system is designed to automate the process of loading tools into the machine and prevents the wrong tool from being loaded. Using RFID tags embedded in toolholders or 2D (presetter-printed) barcode labels for data carriers, ToolConnect reads the data at the machine via scanner or RFID read station.

Zeiss Digital Microscope for All-in-Focus Imaging

Zeiss’ Visioner 1 digital microscope features Micro-mirror Array Lens System (MALS) technology and real-time, all-in-focus optical inspection. The company says that classic inspections systems offer shallow depth of field, meaning that parts of the sample may not be in focus, which can lead to missing features, user fatigue and incomplete inspection.

Sumitomo Coated Turning Grades Designed for Improved Wear Resistance

Sumitomo’s coated turning grades for heat-resistant alloys includes the AC5000S Series for high-efficiency machining. AC5005S features a newly developed heat-resistant, cemented carbide base material, which Sumitomo says has excellent high-temperature hardness and strength for wear resistance and plastic deformation resistance during processing.

Walter Milling Cutters and Grooving System for Machining Efficiency

Walter Tools offers a variety of cutting tool technologies to improve machining efficiencies. The Walter Xtra∙tec XT M5130 family of milling cutters and the Walter Cut DX grooving system are said to provide a positive locking system and reduce indexing time by 70%.

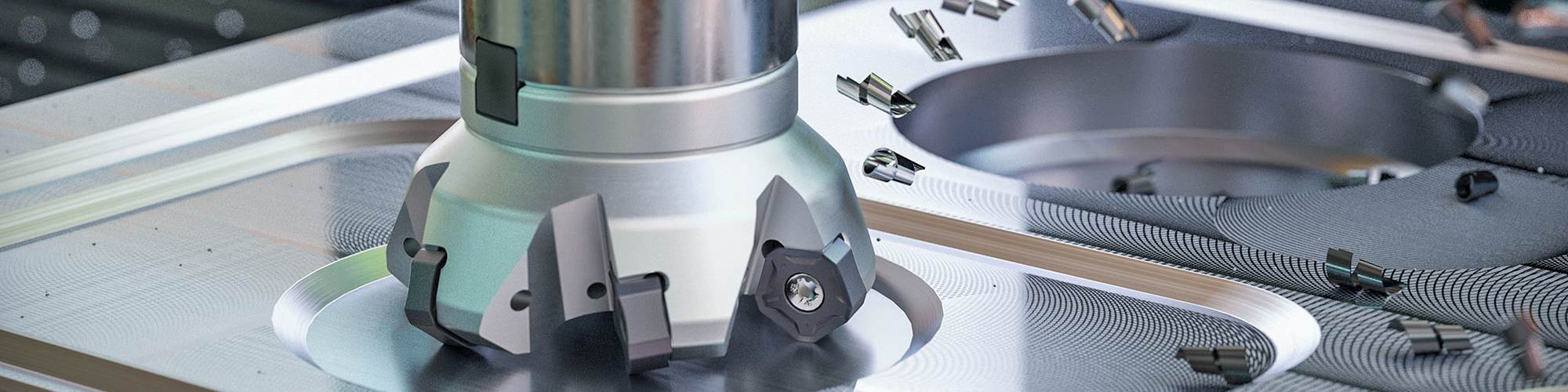

YG-1 Indexable Milling Inserts Enable Higher Feeds

YG-1’s FM10 PNMU face milling indexable inserts combine multicorner face milling performance with high-feed capabilities. YG-1 recommends FM10 PNMU cutters and inserts for milling in steel and cast iron.

Precision Measuring Systems for Inspection Quality, Performance

Photo credit: L.S. Starrett Co.

The L.S. Starrett Co. manufactures precision measuring tools, gages, metrology systems and more. Its optical comparators, vision systems, video inspection and force measurement systems are developed to enhance quality and performance.

Landscape Source: YG-1

RELATED CONTENT

-

The rapidly increasing demand for high-value threaded parts with exceptionally high length-to-diameter ratios has created a lot of interest in thread whirling technology among American shops and manufacturers.

-

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

-

Understanding how inserts are made provides valuable insight into how their performance can be optimized.