The world is opening up again, making it an opportune time to do in-person research on the latest technology and trends at the Precision Machining Technology Show (PMTS) 2021 set for August 10-12, 2021, in Cleveland, Ohio, at the Huntington Convention Center. Strengthening economic conditions also indicate it’s a good time to consider planning and investing for possible updates in your company’s technology, automation and software to make your business more efficient and productive.

This week, we’re taking a look at cutting tools and toolholders, including an insertable form drill system that addresses the problem of high setup times; solid carbide drills that hold tight tolerances; a quick-change toolholding system featuring mechanical stops and coolant tubes for fast setups; a shrink-fit machine especially developed for shrink-fit collets and small toolholders; and more.

Before you go to the show, don’t miss PMTS show highlights in Derek Korn’s latest column and look for more PMTS Product Previews each week until the show! And don’t forget to register for the show.

For all the latest PMTS product highlights, please visit our extensive PMTS Preview Section which includes new PMTS products posted every weekday up through the show’s opening day.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Click on each link below to read the full PMTS Preview product post:

With its PWP and PWP-D insertable form drill system, Schwanog is said to address the problem of high setup times as the insert holder stays in the machine during insert changeover. This design enables the center height to be unchanged. The insertable carbide tool is ground individually, according to customer specifications and can hold a tolerance of as little as ± 0.02 mm and repeatability is 0.02 mm. The form drill systems are available in various carbide grades.

Scientific Cutting Tools’ solid carbide spotting drills are a valuable first step in the hole-making process. The precise point angle is held to a one-degree tolerance for true centering. Covering a wide range of sizes, tools are stocked with 82-, 90-, 100-, 120- and 142-degree point angles in both AlTiN and uncoated finishes. For optimal performance, it is best to choose a spotting drill angle that is equal to or greater than the angle of the following drill, the company recommends.

Platinum Tooling Technologies Inc., importer of Heimatec live tools and angle heads, offers a new and expanding Citizen tool line. The line includes both live and static tools for most Citizen lathes, as well as all current L Series and new M532 models. These precision tools are designed to optimize the machine’s parameters, resulting in improved efficiency and cost effectiveness, the company says.

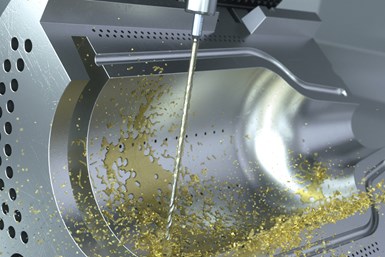

Expanding the diameter range of different drill families, it’s now possible to start drilling at 0.0039” with tools from Mikron Tool. The micro drill CrazyDrill SST-Inox is designed especially for machining stainless materials in diameters starting at 0.0078".

Heule Precision Tools offers a complete line of high precision tooling, including the DL2 deburring tool, which is capable of deburring down to 1.0 mm. It also offers the Cofa, as well as and Cofa-X tools for deburring complex cross bores. The Cofa-X is designed specifically for extreme situations that require specialized cross bore deburring solutions.

Tungaloy’s Coated CBN Grade Inserts for Hardened Steel

Tungaloy’s CBN grade BXA10 inserts were developed to provide extended tool life performance in high-speed continuous cuts. It features a multilayer PVD coating composed of thermally stable TiCN layers and AlTiN layers which provide good adhesion with a dedicated CBN substrate. The line includes an HP-style chipbreaker geometry to provide reliable chip control during finish turning of hardened steel parts.

Angle Heads, Live Tooling Optimize Machining Capability

Benz offers a range of standard tooling for CNC mills and lathes as well as custom solutions per customer requirements. This includes angle heads as well as various sizes of driven tool. In addition to standard axial and radial live tools, the company offers up and down gear ratio tooling, multi-spindles and adjustable swivel heads. In addition, its line of LinTec broaches can create splines, keyways, hex and square features by way of static or reciprocating operation. Benz Solidfix and Capto quick-change systems can be used with its live tools as well as right angle heads and multi-spindle heads.

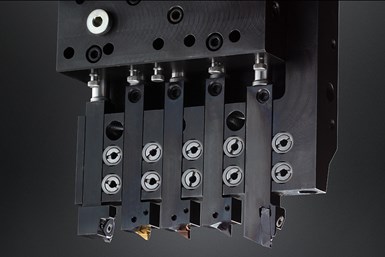

The Horn W&F Linear unit with coolant management is a user-friendly, quick-change system that can be combined with W&F Micro quick-change holders and standard holders. In addition, toolholders without through-coolant ports can be used. Mechanical stops and coolant tubes allow a machine operator to quickly set up or exchange tools.

Haimer’s Power Clamp shrink-fit machine, the compact Power Clamp Air i4.0, enables even and clean cooling for all kinds of shrink-fit chucks and collets, regardless of the outside contour, by using air nozzles without dirt and water residue. The Power Clamp Nano NG i4.0 was specially developed for shrink-fit collets and small toolholders up to size HSK-A63.

RELATED CONTENT

-

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.

-

This quick-change system is aimed at addressing cost concerns for companies focused on conserving costs and improving productivity.

-

A hydraulic chuck and a counter-balanced centering tool, originally developed as in-house solutions, are now available to address the limited working space that is common in Swiss machining.