PCBA Adapter Bridges Acu-Rite CNC to Heidenhain TNC

Appears in Print as: 'Adapter Bridges Between Two Controls on Single Machine'

Adapter gives operators a simple upgrade or ability to switch between two controls on a single machine.

Edited by Angela Osborne

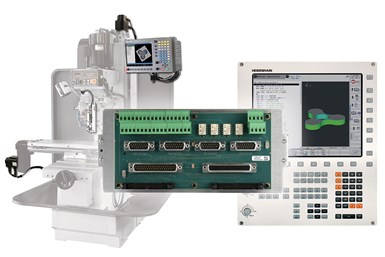

Acu-Rite’s PCBA adapter enables a bridge from an Acu-Rite CNC to a Heidenhain TNC, giving operators a simple upgrade or ability to switch between two controls on a single machine. It bridges the gap to bring an Acu-Rite control user to the next step, which is an an entry-level Heidenhain TNC 320 control — all on the same machine tool.

This system from Heidenhain’s Acu-Rite brand could be especially useful for shop owners who want to easily upgrade a machine which is already equipped with an Acu-Rite MillPwr control to the next-step Heidenhain TNC 320 or to switch between both controls such as in teaching environments at trade schools and in machine shops.

The PCBA was developed to enable Acu-Rite controls users to define and order a TNC 320 for small machine tool applications (such as VMC with toolchanger) as a simple upgrade. This system includes the PCBA adapter, a TNC 320 control and a complete AC package (motors, drives and electrical cabinet).

There are two options available. The kit style is for a user who has an Acu-Rite bed mill kit installed on a machine and they want to add the flexibility of the HeidenhainTNC 320. The interface PCBA adapter can accommodate the functionality by using the backend Acu-Rite components. The use could be educational where most instructing is done on the Acu-rite MillPwr or TurnPwr control, but there is a need to show advance functionality of the TNC 320. This enables users to become experienced with Heidenhain entry-level controls.

The second option is the OEI console-only option which a builder can integrate into the machine, using Acu-Rite’s backend components. This can be used for CNC-ready machines which have older controls and the end user wants to upgrade.

RELATED CONTENT

-

Let’s Talk About Less Machining Chatter

For some turning work, unwanted harmonics can cause chatter and poor surface finishes. A new CNC software capability can automatically compensate for this.

-

CNC Apps You Possibly Didn’t Know You Could Benefit From

Some software capabilities go underutilized. One machine tool builder’s CNC software includes lesser-known apps that shops can leverage to their advantage.

-

Software Controls Chip Breaking in Thread Turning Operations

This cutting tool manufacturer has developed a software module for chip control of thread turning operations in virtually any CNC lathe, even for older machines, using specific tooling and software.