For years, Mazak has touted the advantages of multitasking equipment, ranging from its live-tool QuickTurn and EZ Series CNC turning centers to its Integrex turn-mills with B-axis milling spindles. The idea being shops can machine complex parts complete rather than running them across multiple machines.

At its recent Discover 2021 event held at its national corporate headquarters in Florence, Kentucky, the company introduced a logical next step in this philosophy with its Syncrex line of Swiss-type CNC lathes geared toward high-volume production of small, complex parts. These are the first Swiss-types the company has produced. And they’ll be manufactured at its U.S. headquarters in Florence.

Featured Content

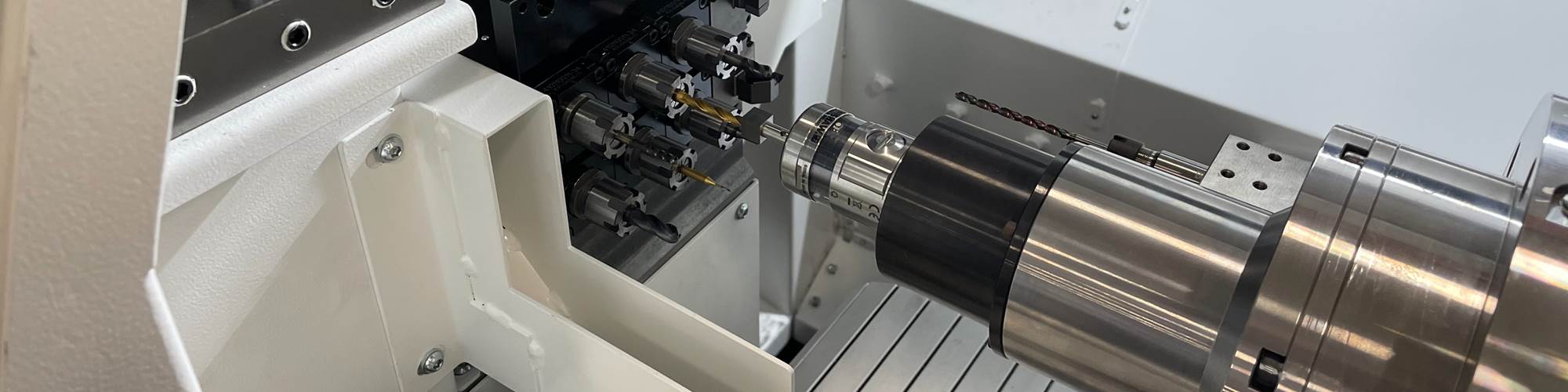

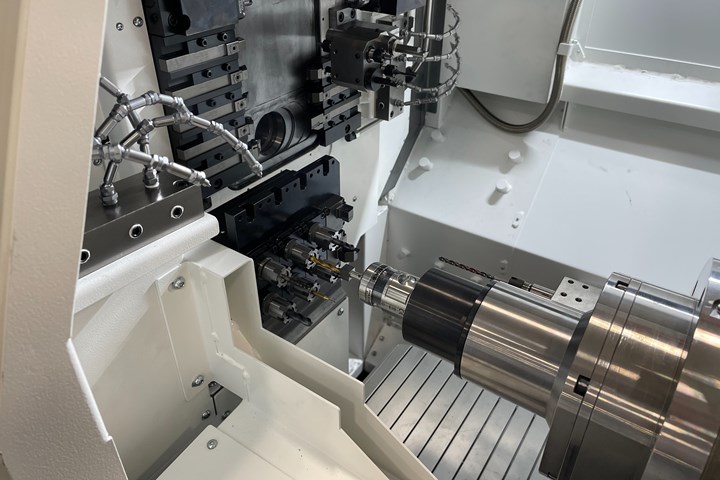

Mazak’s first Syncrex Swiss-type CNC lathes will be available in early 2022 in 20- and 25-mm models.

Why Swiss-types and why now? Kevin Bates, general manager — Mazak Midwest region who has led this program, says one reason is that Swiss-types are no longer niche machines. Instead, they are becoming more common in general machine shops. At the event, he noted that CNC Swiss-types accounted for 10% of the total sales of CNC turning equipment 10 years ago. Today, it’s 20%. And, he says customers have been asking the machine tool builder for some time to come out with a line of Swiss-types.

Initially, the company is offering Syncrex machines in 20- and 25-mm barstock sizes. These models will be available Q1 2022. However, Mazak plans to have larger 32- and 38-mm machines available in the fall of 2022. All machines will be available in 7-, 8- and 9-axis models (The 9-axis models include a swiveling B-axis toolpost to perform full contouring on main and subspindles.) There are 25 tooling stations on the 7-axis machines, 29 for the 8-axis machines and 35 for the 9-axis machines.

In addition, Syncrex machines have a base made of polymer concrete, which is said to be more rigid than conventional cast iron to provide more effective vibration damping and thermal stability. This can lead to longer tool life and better surface finishes.

Syncrex Swiss-types are fitted with the company’s Mazatrol SmoothSt G-code (non-conversational) control as offline CAD/CAM software is commonly used for these types of complex machines.

The machines are fitted with the company’s Mazatrol SmoothSt G-code (non-conversational) control. That’s because the vast majority of programming for complex Swiss-types is performed offline with CAD/CAM software. Mazak has partnered with Esprit CAM and Partmaker in that regard, offering the MT Tablet option to sync with those programs at the machine.

Optional automatic tool setting capability is also available using a Renishaw touch probe that installs in the guide bushing as well as subspindle to touch off tools. This speeds setups by eliminating the need for a setup person do this manually.

Optional automatic tool setting capability is also available using a touch probe, speeding setups for new jobs

Mazak is adding a new building to its Florence campus that will be dedicated to Syncrex machine production. In addition, it is expanding its spare parts building to accommodate support of the new Syncrex Swiss-type line.

RELATED CONTENT

-

Communication: Motivating Employees To Work In The Best Interest Of The Business

Fair treatment is all most employees ask of their employers. Showing both family and non-family employees what is fair and having open lanes of communication allow for a healthy exchange of what constitutes equitable treatment. Effective communication between management and employees on important issues, such as compensation and firm strategy, needs to take place to maintain a motivated and enthusiastic workforce.

-

Re-Turning Adds Life to Train Wheels

Unique turning considerations and circumstances come into play when re-turning well-worn freight and metro rail wheels.

-

Metalworking Vacuum Cleaners: One Type Does Not Fit All

As the metalworking industry becomes more specialized, so does the equipment that cleans it. But as diverse as the industry is, it should come as no surprise that there is no single vacuum that can handle all of its requirements.