Milling Hard-to-Machine Materials on a Micro Scale

The idea of a tool that effectively controls heat with a special grade of carbide, a new coating and internal channels that deliver cooling through ports in the shank where the milling flutes begin, is worth a look.

#micromachining

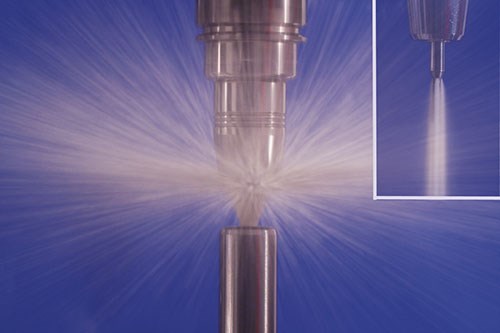

The multiple streams of pressurized coolant at the cutting edges. This method of coolant delivery also flushes chips out of the cutting zone.

Controlling heat at the tool/workpiece interface is an operator’s main concern. Therefore, the idea of a tool that effectively controls heat with a special grade of carbide, a new coating and internal channels that deliver cooling through ports in the shank where the milling flutes begin, is worth a look.

Recently, PM’s sister publication, Modern Machine Shop, published an article titled “Managing the Micro-Milling Process with Tiny Cutters,” in which the author, Mark Albert, explains the CrazyMill Cool solid carbide milling cutters from Mikron Tool.

According to the article, these cutters are capable of significantly higher cutting speeds and depths of cut in tough-to-machine materials compared with conventional end mill designs in this size range. These results are obtainable in stainless steel, titanium, chrome-cobalt alloys and other so-called super alloys. Read more here.

RELATED CONTENT

-

Thread Whirling Basics

The rapidly increasing demand for high-value threaded parts with exceptionally high length-to-diameter ratios has created a lot of interest in thread whirling technology among American shops and manufacturers.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

A New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.