Metalworking Fluid Management and Best Practices

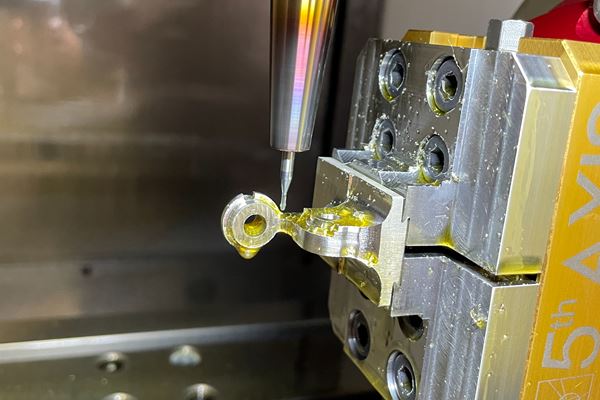

Cutting metal is a complex process involving many critical factors to be successful. Correctly applied metalworking fluids, including oils or coolant, is one of these critical factors.

Automating Cutting Fluid Management

Automation can amplify the benefits of cutting fluid management while reducing the maintenance burden on shopfloor employees.

Precision Machining Technology Review September 2023

Production Machining’s September 2023 technology showcase includes some of the latest technology from Lyndex-Nikken Inc., Kurt Workholding, Master Fluid Solutions, Rego-Fix Tool Corporation and Jorgensen Conveyor & Filtration Solutions.

Master Fluid Solutions Semisynthetic Coolant Improves Sump Life

Trim MicroSol 685XT is designed to provide enhanced corrosion inhibition on all ferrous and nonferrous metals.

Biodegradable Lubricants Eliminate Cleanup Costs

Bio-Air Tool Lubricants perform in many applications, offer better natural lubricity than petroleum-based oils and are safer for employees and the environment.

Bio-Air Tool Lubricants Eliminate Reportable Incidents, Cleanup Costs

These air tool oils provide excellent lubrication for both rotary and reciprocating types of air tools, such as chipping hammers, impact wrenches, air motors, grinders, reamers, drills and more.

Oelheld IonoPlus High-Performance Dielectrics for EDMs

PMTS 2023: The odorless coolant is said to offer increased removal rates, lower electrode wear, excellent surface qualities, lower refill quantities and longevity to provide lower overall operating costs.