Editorial, News, and Products

CAD/CAM Helps Team Win Advanced Manufacturing Competition

Minnesota State College Southeast’s “Average Joes” team took home the grand prize at the 2023 Project MFG Advanced Manufacturing Competition.

Mastercam Appoints New Vice President of Sales

Nicolas Le Moigne brings 23 years of experience working in the CAD/CAM sector, from technical positions through sales and management.

Mastercam Acquires CAM Post-Processing Software Developer

Postability will enable Mastercam users to acquire a broader range of post-processing technology with streamlined support and responsiveness.

Mastercam 2024 Integrates Sandvik Coromant CoroPlus Tool Library

The integrated library enables users to work faster when importing tool geometries and cutting data.

How Small Machine Shops Can Fight Supply Chain Problems

Supply chain disruptions are still presenting challenges in manufacturing. This article examines the effects on aerospace, automotive and medical industries. It also covers ways that machine shops can be successful securing work despite the challenges created by the supply chain.

IMS Software, ModuleWorks, Mastercam Collaborate on G-Code Simulation

IMS Software, ModuleWorks and Mastercam’s IMSce combines IMS G-code emulation with the ModuleWorks simulation and postprocessing technology to provide a G-code parsing solution that connects directly to Mastercam.

Production Machining’s November 2022 News Highlights

Production Machining’s November 2022 news highlights include an event partnership update, industry award, new on-the-job training process, support for manufacturing training, software collaboration and company expansion.

CAD/CAM’s Role in How Machine Shop Benefits from its First Swiss-Type

This manufacturer of high-end RC cars leverages the capabilities of its CAD/CAM software to get the most out of its first Swiss-type lathe even when job batch sizes are relatively low.

Mastercam 2023 Features Multi-Axis, Mill-Turn Advancements

IMTS 2022: The company says one of the software’s top improvements is the ability to consolidate multi-axis toolpaths.

Swiss-Type Turning Point

This northern Ohio shop recently added its first Swiss-type lathe to gain long stretches of unattended machining largely because its continuous efforts to find new operators for its more conventional equipment had proven to be unfruitful.

Mastercam Multiaxis Software Enables Simultaneous 4- and 5-Axis Machining

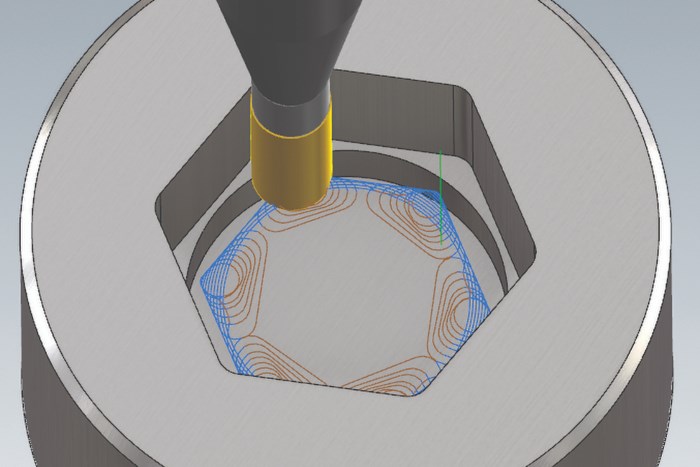

The Multiaxis unified toolpath enables users to select multiple pieces of input geometry to generate the toolpath pattern.

Precision Machining Eastec Technology Preview September 2021

Production Machining highlights some of the latest precision machining advances and technology updates that will be showcased at Eastec 2021, Oct. 19-21 in West Springfield, Massachusetts.

Mastercam Optimizes 5-Axis Postprocessor for FANUC CNCs

Machine unlocks faster and more accurate art-to-part FANUC CNC capabilities.

American Precision Museum Designing New In-Person and Digital Exhibits

Here’s a chance to help preserve industrial history as the museum develops new exhibits explaining the beginning, evolution and direction of U.S. manufacturing.

Why Using Pirated Software is Riskier Than Ever

Machine shops and manufacturers that use pirated software risk losing much more – both directly and indirectly.

Mastercam Partners with Haas on Manufacturing Exhibit

Companies created a waterwheel display for the American Precision Museum demonstrating how running water was turned into power to drive the building.

Mastercam 2021 Designed to Increase Productivity

Mastercam 2021 improves automation, efficiency, connectivity and precision.

Mastercam Joins NCATC as Strategic Partner

The NCATC supports a higher education and industry network that promotes advanced technology applications in workforce development programs and services.

Emerging Leader Keith Goodrich Uses Shop Experience as Trajectory to a Career in CAD/CAM Development

Keith spent years honing his skills in Mastercam software and learning from his coworkers while working at a job shop in Connecticut.

Change the Perception of Manufacturing—Host or Sponsor an MFG Day Event

MFG Day events often serve as the first step toward a manufacturing career for curious students. Here's why you should host one.

Milling Software Introduces Deburring Tool Path Strategy

Eastec 2019: Mastercam 2019 Mill offers expanded machining flexibility, 2D high-speed tool paths, 3D enhancements and multi-axis features to improve shopfloor productivity.

Harvey Tool Libraries Contain Many End Mill Options

Mastercam’s Tech Exchange website now includes Harvey Tool libraries.

Mill Post Processor Provides Support

CNC Software Inc. collaborate with Siemens with milling post processor.

Mastercam Announces Winners of 2018 'Wildest Parts' Contest

The CAD/CAM software developer holds the contest each year to encourage student participation and interest in manufacturing.

The Software Side of Cutting Tools

In CNC machining, there is a significant amount of technology that can be applied prior to making the first chip. This article looks at software enhancement tools that can help optimize the cutting operation before hitting cycle start.

CNC Software Inc. Appoints New Western U.S. Territory Manager

Mike Bebout will further develop the company’s distribution channel and identify areas for growth and improvement.

MFG Day Events Seek to Change Perceptions of Manufacturing

The grassroots movement encourages companies feeling the effects of the skills gap to open their doors to the community and show what modern manufacturing is really like.

CNC Software, Inc. Appoints New Partnership Program Manager

Stas Mylek fills a new position in the company, responsible for developing, managing and supporting an official Mastercam Partnership Program to foster innovation in manufacturing.

Mastercam 2018 Mill Emphasizes Speed and Automation

CNC Software’s Mastercam 2018 mill offers 2D high speed tool paths, 3D enhancements, and multi-axis features that combine with additional enhancements in a package intended to improve shopfloor productivity.

"Race to IMTS" Focused on Helping Shops Increase Their Speed

Widia and CNC Software Inc. are hosting “The Race to IMTS,” a competition focused around challenging distributors and end-customers across the United States, Canada and Mexico to increase their speed through new cutting tool and programming technologies.

Consider the Software Side of Cutting Tools

The intersection of the cutting tool and the workpiece it is applied to represents the very heart of subtractive metalworking. There is a significant amount of technology behind getting the cutting tool into the right place, at the right speed and the correct depth of cut. This article looks at some of the software technology that can optimize the performance of the cutting tool.

Mastercam Celebrates 35 Years in Business

CNC Software Inc., developers of Mastercam CAD/CAM software, started in 1983 when three brothers came up with a concept for programming CNC (computer numerical control) machine tools.

Mastercam and Kennametal Partner to Provide Tool Automation

CNC Software Inc., developers of Mastercam, has partnered with Kennametal Inc. to provide customers with the ability to import tool assemblies from NOVO directly into Mastercam 2018, allowing Mastercam customers to save time searching and building 3D tool assemblies.

CAD/CAM Selection to Fit the Shop

A CAD/CAM system is a large investment and likely will have a strong impact on the buyer well into the future. Careful consideration of all the implications is important.

Mastercam Sails with America’s Cup

The company’s software is being used by Core Builders Composites (CBC), which produces the carbon fiber components used in the construction of the Oracle Team USA’s racing yachts.

Optimizing CNC Legacy Parts with CAM

One day’s work resulted in productivity improvements that allow the equipment to pay for itself, while leaving spare capacity for additional production work.

Tornos Users can now Benefit from Mastercam Swiss CAM

Tornos customers using the company’s TISIS with ISO programming functions can now make use of Mastercam Swiss CAM to speed up programming on Tornos’ line of machine tools.

Mastercam Becomes WorldSkills CAM Partner

The CAM software that competitors in the upcoming WorldSkills 2015 competition have been practicing on for months, honing their programming skills, has become the official software for the machining competitions there.

Mastercam Official Supplier for Worldskills

A few years back, I attended the WorldSkills competition, which was held in Calgary, Alberta, Canada.

Mastercam is in the Cloud

CNC Software Inc. has partnered with Machining Cloud GmbH to provide Mastercam users direct access to the cutting tool product data available on the cloud.

Florida Covets Mastercam Certification

Last month, more than 400 students were certified in Mastercam CAD/CAM software in the Broward and Dade Counties in Florida.

Automate Programming with CAM

Even for those shops still manually programming their simple parts on Swiss machines, there are compelling reasons to automate the programming process now.

Still Going Strong

This year, CNC Software Inc. is celebrating Mastercam's 30th anniversary. It's been quite a journey for this progressive company.

Mastercam Software is Driven with PMPA Member Needs in Mind

Mastercam, developed by CNC Software Inc., is the most widely used CAD/CAM software in the world.

Segue into Swiss Machining a Positive Experience

I thank all of you who gave Mastercam a warm reception at PMTS 2011 where we “soft” launched our new CAD/CAM software package, Swiss Expert.

PM News, June 2011

Kennametal Names New V.P for Global Product ManagementKennametal Inc. has appointed Gretchen W.

Don't Chase Variability with CAM

A recent study showed that mechanical SuperTuning of a moderately priced CNC machine could dramatically improve volumetric positioning accuracy.

Programming Lathes: Eliminate Cutting Air On The Second Pass

Cutting air benefits no one. Eliminate it in the programming department.

Increased Control For Programmers

Here is a CAD/CAM system designed to be inviting to programmers, with a comfortable interface, integrated guides and a learning mode to facilitate operation and allow the shop to start creating tool paths—and turning parts—as quickly as possible.