MachineMetrics Automates Robot Performance Monitoring, Intelligence

Appears in Print as: 'Automatic Robot Performance Monitoring'

Precision manufacturers can now monitor collaborative robots from Universal Robots in real-time to drive automation that improves performance and reliability.

Edited by Angela Osborne

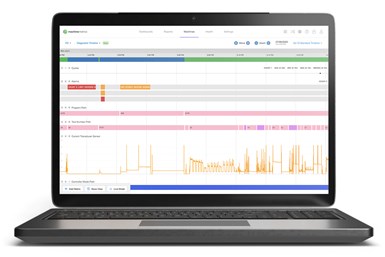

MachineMetrics, a provider of machine connectivity and production analytics for manufacturers, is making its Connector available for Universal Robots (UR) to easily connect to and capture valuable data from any equipment from UR. This latest connector, now available through the UR+ program to all current UR cobot users, enables instant insights into the health and performance of its cobots. Now manufacturers can maximize the uptime of their cobots to increase productivity and drive additional throughput with no additional head count.

“MachineMetrics, like Universal Robots, is at the forefront of delivering innovative solutions that lower the barrier to automation for manufacturers,” says Christopher Savoia, regional head of the UR+ Ecosystem. “Their unique ability to deliver real-time insights into the health and performance of UR collaborative robots means increased reliability, uptime, and productivity of automated work cells.”

Monitoring collaborative robots (cobots) from Universal Robots in real-time can drive automation that improves performance and reliability. “Connecting to and capturing real-time data from manufacturing equipment is what enables our customers to quickly and easily understand their production performance and the health of their machines,” says Bill Bither, MachineMetrics CEO and co-founder. “By connecting UR cobots to MachineMetrics, users can now gain real-time insights into cobot productivity, alert teams when issues arise, and remotely troubleshoot and diagnose issues to get the cobot back up and running.”

It is said manufacturing is undergoing a resurgence as business owners look to modernize their factories and speed up operations. According to Research Dive’s newly published report, the global cobot market is predicted to grow at a stunning CAGR of 41.2% by 2026. It is said cobots deliver a cutting-edge solution that makes it easier to automate manual tasks such as the loading and unloading of materials and parts, leading to major productivity gains and boosting throughput with no additional head count. But, like all machines, ensuring these cobots run to their potential is paramount to their success.

MachineMetrics’ connectivity system is designed so customers can capture data from any piece of factory floor equipment in minutes. The company says users can install it themselves without the need for expensive and time-consuming system integration work. Once installed, the data is instantly and securely streamed to the MachineMetrics Cloud Platform where users can visualize and analyze data from any asset.

“Extending the value of MachineMetrics to drive automation is the next generation of solution for manufacturers,” Bither says. “On its own, MachineMetrics can let the right person or system know at the right time what is happening to keep machines running. In an autonomous factory powered by MachineMetrics, machine data can trigger an action by a robot that feeds the bar into the machine without human intervention.”

RELATED CONTENT

-

Seco Machine Monitoring for Maximizing Manufacturing Efficiency

This complete machine connectivity ecosystem is said to enable manufacturers to use machining data to eliminate bottlenecks and boost overall equipment effectiveness.

-

A Fitting Machining Process

Diversified Fittings has turned to twin-turret/twin-spindle equipment and machine monitoring to become more efficient producing hydraulic fittings and adaptors.

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.