Universal Robots’ (UR) cobots can be programmed through the teach method by simply moving the arm through desired waypoints that are added to the program on the teach pendant. When the cobot was in use, Toolcraft used the UR simulator to create the entire program for the parts rinsing and drying station offline, inserting the waypoints as they transferred the program to the teach pendant. (Photo credits: Universal Robots)

When a large order necessitated adding a third shift, Monroe, Washington-based machine shop Toolcraft was having trouble hiring anyone to cover it. However, by investing in a cobot, the small shop achieved 24/7 production as well as time savings and increased throughput.

“Nobody wants to run on third shift around here,” says Steve Wittenberg, Toolcraft’s director of operations. In an area with 3% unemployment, the shop was not getting much response to its “help wanted” ad. So he started looking at different automation options, initially considering traditional industrial robots.

Featured Content

Looking solely at hardware, Wittenberg initially believed traditional robots would be the more cost-effective solution.. But once the shop started factoring in the savings on not having to erect a safety cage and the time saved on the ease of use, avoiding a lot of complex programming, a cobot from Universal Robots ended up being the right solution, he says.

Cobot Works the Night Shift

The order spurring this investment was for a multithreaded part for a medical device. This part needed to be loaded into a three-step CNC machining operation that would run during a third shift. Toolcraft discussed the challenge with Rapid Design Solutions, a certified systems integrator of Universal Robots.

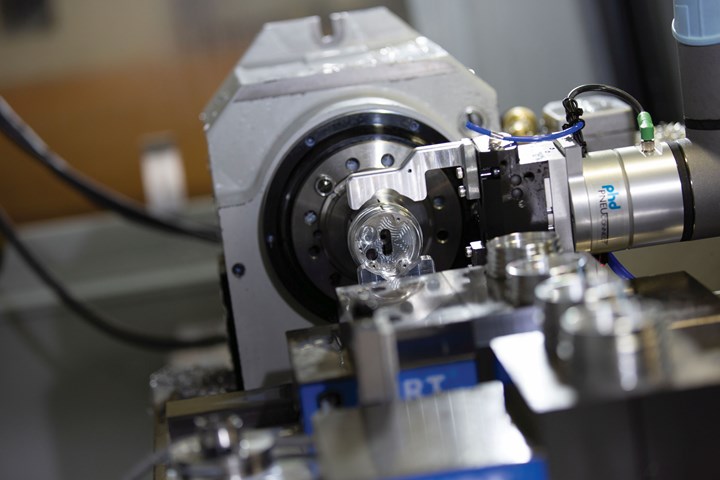

Featuring 30-micron repeatability, the UR5e cobot was able to precisely insert the multithreaded part into the fixturing. The CNC cycle includes three operations in a vertical machining center: two in vise fixtures and one in a fourth-axis rotary unit.

“When you’re doing multioperation precision machining, the accuracy requirements go way up,” says Rapid Designs Solutions owner Troy Ojalehto. “When we heard that the repeatability of the UR5e cobot was down to 30 microns, we were very excited. That really competes in the same space as traditional industrial robots, so that was huge for us. I have not seen other cobots handling this level of precision with multioperation parts like this, with raw stock going in and completed precision parts coming out.”

Six months after implementation, Wittenberg says that Toolcraft saw a production increase right away. He notes the shop was able to “staff” a third shift with the cobot and went from producing 255 parts a week to 370 parts per week. Along with that, it was able to finish the year’s production seven weeks early, thus freeing up that machine to produce parts for other jobs.

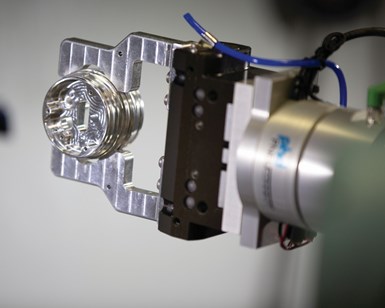

Toolcraft chose the PneuConnect gripper from PHD as end-of-arm-tooling for the UR5e. Being UR+ certified means the gripper is certified to work seamlessly with UR cobots, with all programming software integrated directly on the UR cobot’s teach pendant.

Cobot Cleans Up

While the cobot successfully helped the shop implement 24/7 production, it still was working to its full potential. The machining cycle lasts a total of 56 minutes, but the UR5e is only busy tending parts for six minutes. “The rest of the time, the cobot was just hanging out waiting for the next cycle, “ Wittenberg explains. “We wanted to keep it busy.” Therefore, to occupy more of the cobot’s time, the shop added a parts rinsing and cleaning station.

As the UR5e takes the machined part out of the machine, it dips the part into a rinsing solution, passes it through an air jet, and places the washed and dried part on a rack for shipping. Toolcraft was also able to control the pneumatic fixture and door actuators through the UR5e I/O interfaces. “This greatly reduces the need for CNC wiring and preserves all the control’s standard safety functions,” Ojalehto explains.

Learning to Program

While Toolcraft enlisted the assistance of a system integrator to get the initial application up and running, the shop was able to program and install the rinsing and drying station on its own. “What really enabled us to do this was all the free online support Universal Robots gives you,” Wittenberg says. “After our automation engineer took the online UR Academy course, he spent a few hours with the integrator and was able to add that station to the cobot cycle.”

At first, Wittenberg feared that production would go down during the rinsing station’s programming phase since the cobot would be pulled away from its regular machine-tending duties. The team discovered, however, that they could use Universal Robots’ simulator and program almost the entire addition to the cycle offline while the cobot kept working.

The offline program is simply loaded via USB directly into the UR5e’s teach pendant. “In the program I did in my office, I’d just set blank waypoints,” says Brian Laulainen, Toolcraft’s automation engineer. Once I was next to the cobot, I was able to quickly use the free-drive motion and move the robot into the correct positions and teach the new waypoints.”

The next task he expects to be automated on the shop floor is tending a horizontal machining center. “That’s a potential challenge, because the mill uses rotary tombstones that are swapped in and out of the milling machine, which creates some difficulties with fixturing,” Wittenberg says. “But we’re confident we can solve those issues using a Universal Robot and some innovation in fixturing.”

RELATED CONTENT

-

Robot Readiness: Taking Initial Steps Toward Integration

Not confident enough about automating a process yet in your machine shop? These considerations will help you better understand the path to robot adoption.

-

Advanced Automation Answers Demands

How can we utilize automation in our facilities to create a better worker experience and increase throughput?

-

Replace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.