Machine Monitoring Software Update for Improving Efficiencies

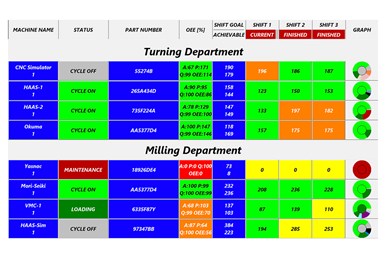

Dashboard additions display how many cycles were done on previous shifts, the machine monitoring timelines of previous shifts and a pie chart of the machine utilization for the current shift.

#Industry40

Edited by Angela Osborne

Detailed graph monitoring dashboard. Photo Credit: eNet Monitoring and DNC

The eNet Monitoring and DNC machine monitoring software updates — eNET V9.1 and eNET LT V5.1 — include two new machine monitoring dashboards (detailed timeline and detailed graph) which display the shift goal for machine cycles that can be accomplished per shift, and the achievable cycles that can still be completed on the current shift. The dashboards also display how many cycles were done on previous shifts, the machine monitoring timelines of previous shifts and a pie chart of the machine utilization for the current shift.

The new software versions also provide improvements to the legacy machine monitoring dashboards, as the interface code has been refreshed to operate even faster and enable more visual customizations of the dashboards, the company says. It is said a new API that is over 200% faster has been added to talk to eNET partner softwares. The SQL interface has also been refreshed to improve ease-of-use and offer more features.

The software updates are available for all eNet machine monitoring customer as a complimentary download from the company’s website, as eNET Customers can utilize free software updates and phone support without yearly maintenance fees.

RELATED CONTENT

-

Machine Monitoring Solution Enables Real-Time Communication

IMTS 2022: Scytec DataXchange machine monitoring solution from Shop Floor Automations captures data in real time and monitors for a variety of applications.

-

Seco Machine Monitoring for Maximizing Manufacturing Efficiency

This complete machine connectivity ecosystem is said to enable manufacturers to use machining data to eliminate bottlenecks and boost overall equipment effectiveness.

-

Vericut 9.4 Offers Increased Connectivity Across Manufacturing Workflow

The latest version features a new module, CNC Machine Monitoring, which connects Vericut directly to CNC machines and streams data to enable users to monitor what their machines are doing on the shop floor, live in real time.