Turning superalloys on a machine is challenging. These often stubborn materials can be tough on carbide cutting tools and produce long, stringy chips that wrap around parts and leave behind a poor surface finish. Breaking short chips with this material was a struggle for one job shop until it discovered a new technology in a Swiss-type machine it recently purchased.

Prior to discovering the technology that has drastically altered the way it machines jobs on a Swiss-type lathe, Slabe Machine Products (Willoughby, Ohio) relied on high-pressure coolant in order to break chips and remove them from the cutting zone. However, with this process alone, it can be difficult to correctly position the coolant stream at the perfect angle and pressure to be successful.

Featured Content

When Slabe Machine bought its first Marubeni Citizen-Cincom Swiss-type lathe that came equipped with low-frequency vibration (LFV) technology in 2018, the job shop experienced immediate advantages, including short chips, improved tool life and part surface finish, time savings, and overall increased productivity. In fact, the company was so impressed with the machine that in a year’s time it purchased 10 more of the Swiss-types with LFV.

But, what is LFV and how does Slabe Machine apply it?

Spearheading Innovation

Fully embracing new technology such as LFV is not out of character for Slabe Machine. The company is known for being at the forefront of innovation, according to co-owner Brendan Slabe. “We typically dive in at the onset of any new technology,” he says. “People drive the engine, but technology is a close second. If you have a nice merging of technology and people, you have a winning recipe.”

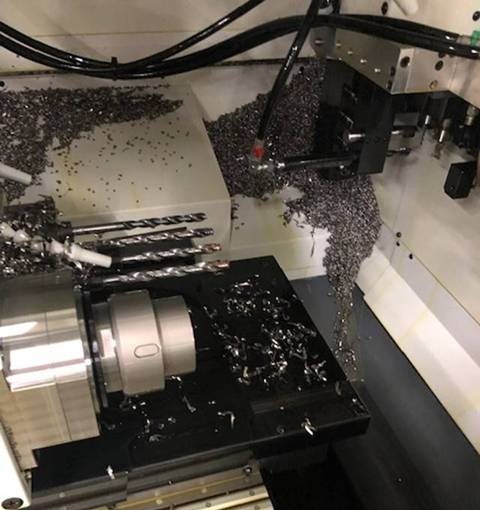

After experiencing the “game-changing” technology of LFV on its first Marubeni Citizen-Cincom Swiss-type lathe equipped with the technology, Slabe Machine bought 10 more machines just like it within a year. Photo credits: Slabe Machine Products

Serving industries such as aerospace, firearms, medical, power generation, valves and bearings, the job shop accepts a variety of work that requires an array of machining capabilities. Therefore, Slabe believes in staying abreast of the latest innovations to always be positioned to meet customers’ increasingly demanding expectations. He says his company was one of the first to purchase multi-axis machines, and he makes a point to have the latest technology for turning machines, CNC tool and cutter grinders, Swiss-type machines, 3D printers and waterjet machines.

So, when Slabe Machine’s distributor for Marubeni Citizen-Cincom machine tools, Concentric Corp. (Cleveland, Ohio), suggested that the shop try LFV technology, Slabe ran with the idea. He purchased a Citizen L20 Swiss turning center on which it completed turning, grooving and drilling operations with LFV.

Slabe calls the time when he discovered how well this technology works a “eureka” moment. “We found a magical sweet spot where our tools went from lasting 50 pieces to lasting for 500,” he explains.

Vibration? No Problem

Although vibration is usually unwelcome in a machining process, low frequency vibration, developed by Citizen for its Swiss-type lathes, has proven to be beneficial to Slabe Machine in many ways. Because the technology is designed especially for difficult-to-machine materials — such as Inconel, Hastelloy, stainless steel, copper and aluminum — it has worked wonders on the job shop’s 11 Marubeni Citizen-Cincom sliding headstock Swiss-types, which include L12, L20 and L32 models.

How does vibration work to a cutting tool’s advantage? LFV technology purposely oscillates the cutter in the Z-axis in time to the rotation of the barstock. At times, it brings the cutter completely out of the cut.

Although vibration is usually unwelcome in a machining process, low frequency vibration has proven to be beneficial to Slabe Machine in many ways.

Marubeni Citizen-Cincom says the intentional air cuts break the chips into consistently small pieces so they can be readily expelled, minimizing the problems of spiraling chip entanglement around the workpiece or tool, known as “bird nesting.”

“It sounds like problematic vibration when LFV is in use,” Slabe explains. “But the tool only detaches from the workpiece for a nanosecond, it reengages and makes the chips into almost milling-like (small) chips. Tools last remarkably longer.”

Chip Size Control

The Swiss-type lathes that contain LFV also provide the ability to perfectly control chip size. “LFV is highly engineered oscillation synchronization through the machine drives,” explains Matt Klecka, vice president of sales at Concentric Corp. “Its control is as simple as changing variables in one line of program code to change your chip configuration.”

Slabe Machine used multiple 3/8-inch drills that penetrated close to five inches deep in this application, which once produced long, stringy chips that affected tool life and surface finish. But short chips are now produced by using LFV’s programming within the machine control.

To find the perfect chip for optimal throughput or the “sweet spot” as Slabe puts it, it might take some trial and error on behalf of the machinist. He explains that there is no handbook to reference when finding the right parameters where the tool is performing perfectly and when the chip will break at just the right time. He adds that he believes tribal knowledge is involved.

Slabe cites a specific example of when LFV created shorter chips for a Hastelloy application at the job shop with “no more strings.” Here, the company used multiple 3/8-inch drills that penetrated close to five inches deep. “We used to have long, stringy, heat-holding, carbide-tool-killing chips that would randomly wrap around the drills and force us to stop the process midway through in order to pull and purge them,” he says. But now they are small – just how he likes his chips.

Minimized buildup on cutter edges, reduced heat generation and power consumption are additional benefits of LFV technology, according to Marubeni Citizen-Cincom. In addition, the same type of cutting tools Slabe Machine uses for conventional turning can also be used for LFV turning. The company uses it for drilling, grooving and threading operations as well. In the case of grooving applications, the grooving tool oscillates/plunges in and out normal to the barstock circumference in the X-axis.

Productivity Increases

After implementing one Swiss-type machine with LFV, Slabe Machine quickly experienced longer tool life, improved surface finish of

Slabe says LFV has introduced opportunities to machine new types of parts on his Swiss-type lathes that previously were done on other machines. For example, aerospace tip shells are now machined on the Swiss lathes.

workpieces, and time savings for the machinist and the business overall. These benefits all equal increased productivity for the company. Because of these results, Slabe made the decision to purchase more machines with LFV. The timing was right because all the company’s Swiss machines were needing replacement due to old age.

“I was planning on replacing the machines one at a time, but I just decided to replace them in under a year because the efficiency advantages were so great,” Slabe says, noting that he likely won’t buy another Swiss-type that didn’t incorporate this technology.

Slabe says LFV has introduced opportunities to machine new types of parts on his Swiss-type lathes that were previously done on other machines. For example, aerospace tip shells are now machined on the Swiss lathes. He explains that, in the past, the company gun-drilled the holes for these parts on a separate machine, but now the holes can be drilled on the Swiss. “Typically, the Swiss machines didn’t have the strength or horsepower to drill half-inch holes four or five inches deep,” he says. “But now it cuts a little bit freer because it’s only cutting incrementally with LFV technology.” He adds this type of "high-speed machining" enables lighter cuts while using less horsepower compared with conventional processes that require higher horsepower and heavier cuts.

Marubeni Citizen-Cincom Inc. | 201-818-0100 | marucit.com

Slabe Machine Products | 440-946-6555 | slabemachine.com

RELATED CONTENT

-

Making Parts on a Swiss/Laser Machine

Adding laser cutting to Swiss-type machining is helping this shop do more work for its customers in the medical industry.

-

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.