Editorial, News, and Products

Manufacturer Mulls Long Versus Short Bar Feeder

A manufacturer of gears and gear assemblies decided four-foot magazine bar feeders made more sense than 12-foot, single-barrel bar feeders.

Bar Feeder for Sliding Headstock Lathes Enables Higher RPMs

PMTS 2023: The LNS GT 342 automatic magazine bar feeder is designed to enable fast and easy diameter changeovers and improved productivity.

LNS Turbo MH140 Chip Conveyor Filters Mixed Chips

The Turbo MH140 filtering chip conveyor is designed to prolong coolant life, reduce tool wear, protect coolant pumps from damage and reduce coolant tank maintenance.

Growth Comes When Machining Challenges Are Met

Manufacturers such as SDP/SI that embrace machining challenges ultimately find ways to become more efficient and profitable operations.

VIDEO: A Unique Innovation Keeps the Wheels Turning

A problem with a bicycle’s two-piece bottom bracket design spurred action from two friends that led to not only a simple solution but to a business venture with in-house machining capability that has become an international supplier to high-end bike manufacturers.

All-Electric Bar Feeder Optimized for Lights-Out Production

IMTS 2022: The Quick Load Servo 105 automatic bar feeder has a 26" (650 mm) heavy-duty magazine which can stage up to 1,430 lbs of barstock for long unattended and lights-out production runs.

Swiss-Type Turning Point

This northern Ohio shop recently added its first Swiss-type lathe to gain long stretches of unattended machining largely because its continuous efforts to find new operators for its more conventional equipment had proven to be unfruitful.

LNS Compact Filtering Chip Conveyor Eliminates Contaminants

Chip conveyor features dual conveyor system and self-cleaning filter drum to manage chip materials of all shapes, sizes and weights.

LNS Bar Feeder Control Enhances Machine Health Monitoring

The company says the control enhances the user-friendliness of the Quick Load Servo S3+, a bar feeder that is well suited for unattended and lights-out production thanks to its robustness and reliability.

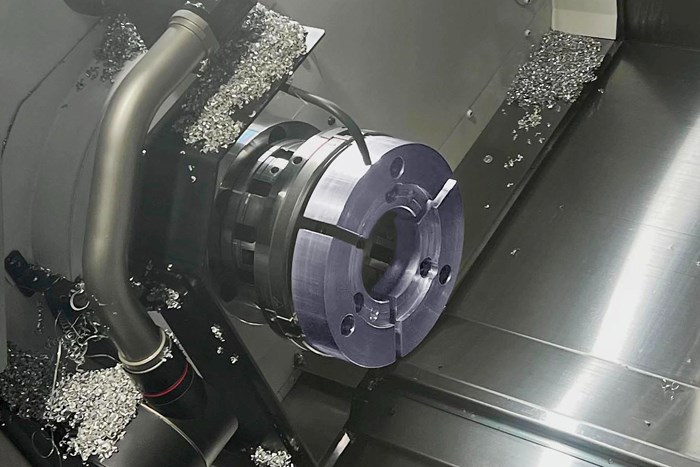

A Fitting Machining Process

Diversified Fittings has turned to twin-turret/twin-spindle equipment and machine monitoring to become more efficient producing hydraulic fittings and adaptors.

LNS Oil Mist Collector Provides 98.3% Filtration Levels

An optional HEPA filter kit uses recyclable E11 filter media for even greater results.

LNS Compact, Mobile Spray Cabin Eliminates Contaminants

LNS Spray Cabin keeps workplace air and surfaces aerosol mist-free when cleaning parts

Production Machining Industry News, October 2019

Company partnerships, new hires, new credentials for CAM, a grand opening, and more are among the news in the precision machining industry this month.

Bar Feeders Evolve to Interconnectivity

Bar feeding continues to broaden its contributions to making turned parts faster and better. Ethernet interconnectivity can be the next step to increased profitability.

LNS Oil/Coolant Mist Collector Accessory Kit Allows Easy Installation

Included in the kit are adjustable mounting rails, a sealed connecting plate, splash guard and airflow regulator.

Ethernet Communications System Enables Interactivity Across LNS Product Lines

e-Connect enhances the performance of additional LNS products including chip and coolant management devices, high-pressure coolant and air filtration systems.

LNS Bar Feeder Loads Small Bar Diameters

PMTS 2019: The GT 112-E automatic magazine bar feeder from LNS is especially useful for sliding headstock machines running unattended or lights-out production using small bar stock.

LNS Acquires ChipBlaster

ChipBlaster, the maker of high pressure coolant systems, coolant chillers, cyclonic filtration systems and other machine tool peripherals, has been acquired by LNS.

LNS Acquires ChipBlaster

The LNS Group has acquired ChipBlaster Inc., the maker of high pressure coolant systems, coolant chillers, cyclonic filtration systems and other machine tool peripherals.

Heimatec Sells Tecnicrafts' Products for Swiss Turning

Heimatec Inc. is selling collets and guide bushings from Tecnicrafts Industries that are exclusively used for Swiss turning applications.

GT 112-E Bar Feeder Loads Small Bar Diameters

LNS’ GT 112-E automatic magazine bar feeder has a dual U-shaped guiding channel with a sectional guiding channel cover, combined with a self-centering bar clamping system that matches the entire diameter range of the lathe.

Preparing for Lights-Out Production

As manufacturers face the challenges of reducing cost-per-part while meeting quality and delivery demands, adding a workerless third shift is a tantalizing possibility. It’s also a bit scary.

Oil/Coolant Mist Collector Addresses Efficiency Challenges

These oil/coolant mist collectors can contribute to employee safety and a better work environment all around.

Choosing an Automatic Bar Feeder

The bar feeder is the most common form of automation for turning operations. Selecting the right one requires consideration of the applications for which it will be used.

Streamline Production with Standardized Processes

To alleviate overlap in communications for the manufacturing community, the MTConnect standardized protocol was developed for CNC machines and other manufacturing equipment.

Celebrating 40 Years by Giving Back

To honor the 40th anniversary of LNS Group (based in Orvin, Switzerland), the company’s more than 800 employees have committed to give back to their communities through public service.

Competition and Technology Drive the Pace of Manufacturing

IMTSTV's Penny Brown recently spoke with Steve Fritzinger, from NetApp, about competition and technology driving the manufacturing industry's pace and why companies must adapt to this change if they want to survive.

Shopfloor Data and the Future of Manufacturing

Redundancy is far too common in many areas of life. Standardized processes that streamline production might be the perfect solution.

Technologies for Chip and Coolant Management

To the casual observer, removing the chips created during a metalworking manufacturing process may seem about as complicated as emptying a waste basket.

Working Smarter

In today’s intensely competitive manufacturing environment we all strive to improve productivity and profitability.

Communication Among Workcell Components

An Ethernet-based system acts as a conduit for relaying operational data between the programming software, controller, bar feeder, machine tool and parts unloader.

The Evolution of Feeding Barstock

When the ancient Egyptians employed the first known turning machines, productivity was probably not a top-of-mind issue. Given an abundance of slave labor, it’s likely the pharaohs enjoyed relatively low production costs. Today, of course, improving productivity is critical in any manufacturing operation that does not rely on plentiful, cheap labor.

PM News, June 2011

Kennametal Names New V.P for Global Product ManagementKennametal Inc. has appointed Gretchen W.

PM News: March 2011

Cleaning Technologies Group Names New PresidentTim Piazza was named president of Blackstone-NEY Ultrasonics.

Take the Highland Road

From programming to setup to production, this Ohio job shop plans everything it does around untended machining. The company has been refining the process for more than a decade and has become very good at it.

Ethernet Communications System Reduces Material Waste

Communication between a bar feed and machine tool can save on remnant cost.

January 2010 News

600 Europe Appoints New Managing DirectorMike Berry has been appointed managing director of 600 Europe, responsible for managing and developing the Group’s newly centralized machine tool business in the U. K.

PM News August 2009

Swiss Bar Feeder Announces Ambitious Growth and Expansion PlansSwiss company LNS announces considerable plans for growth and expansion into new markets. "The goal is to double the size of our company within five years," explains Thomas H.

Bar Feeders Provide New Paths to Productivity

The lastest advances in bar feeding can help you prepare for the coming manufacturing resurgence.

Bar Feeders with Synchronization

The Alpha ST 212 and ST 320 bar feeders provide reliability, stability and ease of operation, the manufacturer says. Model ST 320 feeds round barstock from 0. 12" to 0.

Successful Untended Operation

Machine tool accessories can make or break untended operation.

Bar Feeders And Workpiece Surface Finish

Quality surface finish of a part is not only dependent on the turning machine itself, but also on the barstock loading and support system. The bar feed system becomes critical to the surface finish outcome by enabling the turning machine to create the desired finish and/or by protecting the existing finish.

Barfeeders Have Come A Long Way

From the perspective of a barfeeding solutions company, this is an exciting time for the screw machine industry. We see our customers turning out a variety of parts, many of which are made to the tightest tolerances ever. We also find that they are rethinking their entire manufacturing process to improve productivity a

Efficient Operation With High-Pressure Coolant

Manufacturers spend millions of dollars on liquid coolants each year to help machine tools cut metal more efficiently. In many cases, however, the effect of this coolant could be greatly enhanced—in some applications by 100 percent or more—by using a high-pressure coolant delivery system.

Accurate Barstock Alignment Provides Faster Speeds

Recent developments in sliding-headstock turning machines allow for faster feed rates and higher spindle speeds—both aimed at increasing throughput to improve productivity. Sometimes, though, these machines cannot reach their full potential because of other equipment that runs in conjunction with it.

Productivity Increases With Automatic Short-Load Bar Feeder

This company was skeptical about replacing its 12-foot bar feeders with an automatic, short-load system until it tested one manufacturer's system.

Right Barfeed For The Job

In today's competitive market, customers demand products that are better, less expensive and delivered faster. This, of course, means manufacturers constantly struggle to improve both productivity and product quality.