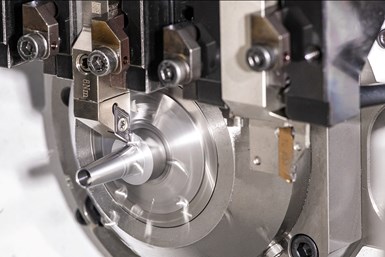

Iscar Neo Swiss Quick-Change Toolholders for Swiss-Types

Appears in Print as: 'Neo Swiss Quick-Change Toolholders for Swiss-Types'

IMTS 2022: Neo Swiss modular quickchange tooling line for Swiss-types feature a rotary wedge mechanical design for clamping rigidity and accuracy.

Edited by Angela Osborne

Photo Credit: Iscar

Iscar’s NEO Swiss modular quickchange tooling line for Swiss-Type machines are designed to provide rigidity and accuracy. The line is said to have a robust rotary wedge mechanical design for clamping rigidity.

The company says rigidity is important due to the nature of the processes on Swiss machines and the difficult materials which are often machined, meaning that depths of cuts can be deep which can compound the need for an extremely rigid system. Accuracy is also essential when changing tools for part requirements and achieving seamless changeover from job to job. The repeatability of Iscar’s NEO Swiss tools is ±.0008” (±0.02 mm).

According to the company, materials cut in Swiss shops make holders that are coolant through a critical factor in part quality, tool life and chip control. Iscar says it incorporates this technology everywhere with NEO Swiss heads’ coolant holes strategically placed (in some cases at the top of the insert and underneath the insert edge) for efficient coolant introduction. No bulky tool head is needed, which helps eliminate the possibility of chips getting caught on heads or coolant nozzles, the company says.

Also available in the ISO Turn Neo Swiss head is a Y-axis option, which can add rigidity to turning operations by inverting the insert from X-axis to Y-axis orientation, thus changing the cutting forces from radial (perpendicular to the shank) to axial (parallel to the shank). This orientation is also said to improve chip evacuation in tough chipping materials by positioning the insert inverted, taking advantage of gravity to project chips into the conveyor.

The NEO Swiss line comes in 0.500", 12mm and 16mm shanks with planned expansions.

RELATED CONTENT

-

Flexible, Quick-Change Tool Adapter System for Live Tools

The system significantly reduces inventory and changeover time for lathe users.

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.

-

Goeltenbodt Pre-Settable, Quick-Changeable Tooling System for Swiss-Type Lathes

IMTS 2022: The company says the system can provide quick and easy tool changeovers and is pre-settable off the machine with repeatability of .0004″.