Is the German Apprenticeship Model the Answer for U.S. Manufacturing?

Appears in Print as: 'Is the German Apprenticeship Model the Answer?'

This machine tool builder president and CEO is an ardent proponent of the German apprenticeship model and believes this concept could be applied here in the United States to address the skilled labor shortage.

#workforcedevelopment #columns

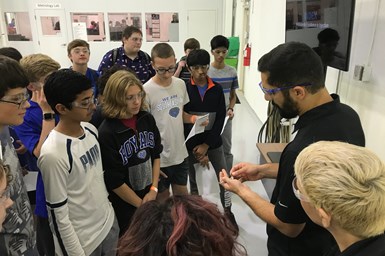

Cris Taylor, president and CEO of Index Corp., believes nothing is as effective at combating outdated stereotypes as partnering with local high schools and introducing students to clean, state-of-the-art facilities, such as Index’s North American headquarters in Noblesville, Indiana.

Photo credit: Index Corp.

In Germany, the Vocational and Educational Training (VET) system plays a vital role in preparing young people for careers in their chosen field. This approach traces its roots back to the 12th century when German craft guilds established the apprentice-journeyman-master approach to learning a trade. Today, there are 326 recognized apprenticeship occupations, spanning diverse fields, including advanced manufacturing, IT, banking and hospitality.

More than 525,000 German young people completed apprenticeships in 2019. An additional 1.33 million individuals were enrolled in VET programs at that time. In fact, nearly 60% of the country’s youth begin their careers within the system. Still, a shortage persists: more than 53,000 training positions remain unfilled.

Featured Content

The VET system is a tremendous benefit to Germany. The country’s economy relies on a manufacturing base that requires a constant supply of well-trained young people. Apprenticeships maintain this flow, resulting in one of the lowest youth unemployment rates in the EU and the world’s largest trade surplus.

At the ages of 15 or 16, German students select one of two tracks: college prep or apprenticeship. This decision is based on factors including aptitude, opportunity, personal interests and parental input. Students who take the apprenticeship approach sign a contract with a company. For the next 2 to 3.5 years, their education is split roughly between 70% workplace learning and 30% in a vocational high school. Most of them complete the program at 18 and graduate as journeymen ready to join the workforce full time. A substantial number of these opt to continue their education in a traditional university setting. Conversely, many university students choose to complete an apprenticeship, either during their pursuit of a degree or after obtaining it.

While it would not be practical to attempt fully replicating the German approach in the U.S., the model does offer insight into ways we can begin to address the U.S. skilled labor shortage.

Cultural attitudes tend to persist and can be extremely difficult to change, yet shifting the way American society views skilled trades offers tremendous potential. Too many young people, parents and educators view college as the default outcome. Other paths are frequently thought of and portrayed as falling short of that established expectation. Companies often reinforce this mindset, valuing college degrees over experience — both when defining job qualifications and establishing pay scales.

The German apprenticeship model offers insight into ways we can begin to address the U.S. skilled labor shortage.

In reality, many college students in the U.S. take on enormous debt to study subjects that will end up wholly unrelated to their careers. Alternatively, those who take advantage of an apprenticeship program acquire practical skills and enter the workforce at a younger age with significant earning potential and no student loan obligations. Bringing attitudes and expectations more into line with factual, observable outcomes would better serve students and society at large.

Much of this needed change begins with how parents and educators speak with young people. This includes not only conveying the potential benefits of trade careers when compared to attending a traditional college but also affording those careers respect on a daily basis. While the financial advantages of becoming a CNC machinist, electrician, carpenter or other skilled tradesperson are clear and easy to communicate, that message can be obscured by a societal attitude that those jobs are in some way inferior to other career choices.

Exposing people at a young age to the reality of modern manufacturing is a powerful way to change attitudes, as recognized by the growth of Manufacturing Day in recent years. That initiative should be an ongoing, year-round effort for manufacturers who care about the future of the industry. Nothing is as effective at combating outdated stereotypes as partnering with local high schools and introducing students to clean, state-of-the-art facilities, such as Index’s North American headquarters in Noblesville, Indiana.

Furthermore, partnering with schools to develop apprenticeship programs and curriculum can help create a constant stream of future talent for your organization and the industry as a whole. The VET system represents a partnership between education, industry and the government, which establishes baseline standards and ensures they are met. While we are unlikely to reach that level of organization in the U.S., smaller partnerships between manufacturers, high schools and postsecondary institutions will be vital to revitalizing our manufacturing base.

I began my career in an apprenticeship program and I am an ardent proponent of the model. In Germany, 8% of Index’s workforce is currently in paid training. If U.S. companies pursue and achieve similar levels of participation, we will overcome the skilled labor shortage here and ensure the future health of American manufacturing.

About the Author

Cris Taylor

A dual British/German citizen with more than 30 years in the manufacturing industry, Cris Taylor is the president & CEO of Index Corp. He previously spent 27 years at Chiron, including five years as the CEO of Chiron America.

RELATED CONTENT

-

Inventory Control Systems For The Shop

An ongoing effort towards more efficient operations drove this shop to take a closer look at indirect material usage, subsequently leading to implementation of a new system for tracking toolroom inventory.

-

New Line of Swiss-Types for Job Shops Eyeing High-Production Work

Mazak now offers the Syncrex line of Swiss-type CNC lathes — its first — targeting machine shops getting into higher volume production of complex parts.

-

Low Frequency Vibration Increases Job Shop’s Productivity

With the ability to machine difficult materials more efficiently while improving surface finish, this job shop is reaping the benefits of its Swiss-type lathes that incorporate low frequency vibration.