Integrated Tool Management with CAD/CAM Connection

Better organization in a shop usually leads to higher productivity, and often, improved quality. That’s the objective of this modular tool data management software as it consolidates resources to encompass all aspects of production resource management.

Better organization in a shop usually leads to higher productivity, and often, improved quality. That’s the objective of TDM Systems’ modular tool data management software as it consolidates resources to encompass all aspects of production resource management, including tooling and fixtures, measurement and inspection equipment, and all related data.

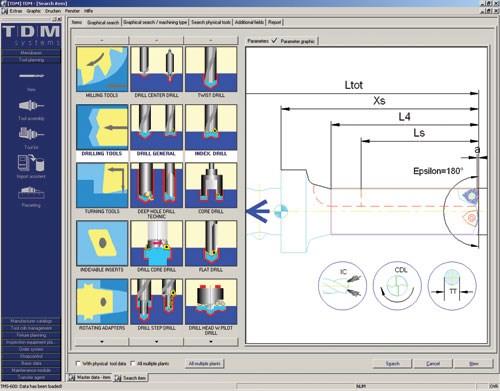

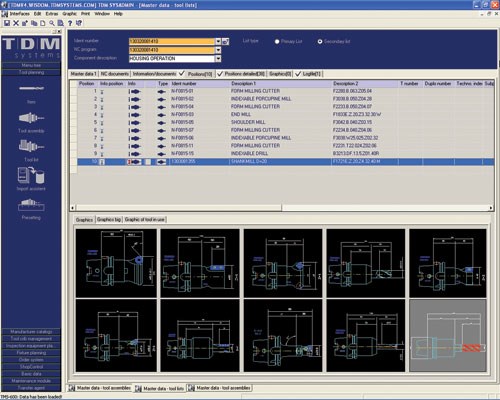

While many software packages offer individual aspects of tool management, such as design, inventory or simulation, TDM is designed to go beyond a single venue. With more than 50 interfaces, it allows users in an organization to take tool data anywhere that it is needed, from purchasing to design and engineering to CAD/CAM to the toolcrib and assembly. Most companies already track this information, but typically in a disjointed way with a variety of techniques. This software provides a centralized database to contain all of the information and permits access throughout the company.

Featured Content

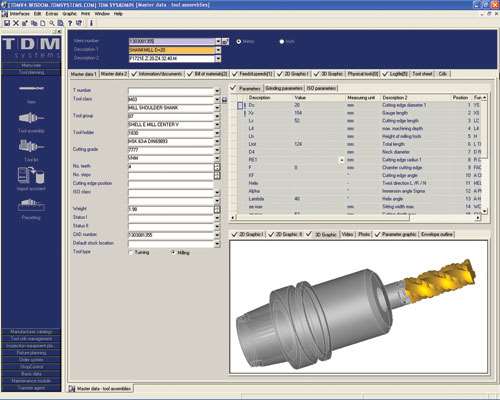

Chris Rezny, executive account manager of strategic accounts, explains, “Tool data can be found in so many places. In design alone, it can be with the part, the tool or the fixture, where you need to know or find the types of tools and the geometric data of the tools. You need to know if you have it in inventory or who the best suppliers are with the best prices. TDM tracks all of that information and more through interfaces with about 25 different ERP systems.” An ID number is assigned to each tool or assembly, and those numbers provide easy access to inventory, suppliers, prices, and so on.

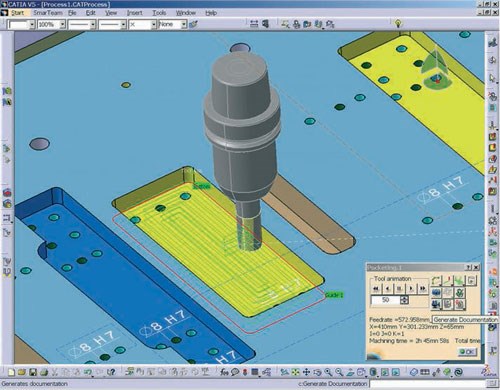

Additional interfaces allow communication with other software packages, including Catia, NX Siemens, Pro Engineer, Tebis, TopSolid, Esprit,

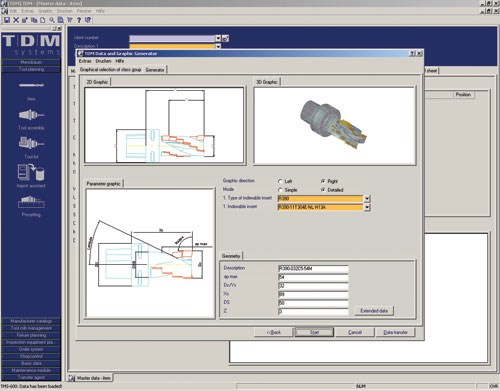

MasterCAM, EdgeCAM and SolidCAM. With the NC program, a profile is brought in from the assembly or a tool list can be created. Feeds and speeds can be supplied by various sources such as catalog data or shopfloor personnel with experience with particular parts or tools. For simulation, high-quality tool data is essential for a realistic collision analysis, and the interfaces provide access to accurate cutting parameters, tool life information and tool allocation. “With only a few mouse clicks, you can create a complete tool data record with true-to-scale and ready-to-simulate 2D and 3D graphics,” Mr. Rezny explains.

“You can also bring in supplier information costing

factors for purchase and then put in percentage of utilization,” he continues. “What was the actual cost to access the tool? This is particularly useful for tools that are reusable. The software can keep track of tool regrinds and interpolate the data into a cost structure.”

On the shop floor, the system manages tools in and out of the tool crib, regardless of the number of tool cribs or locations of vending machines. When a tool is checked in from the supplier or checked out on the shop floor, it can be assigned to a specific job or machine. The system maintains data for scrapped tools or regrinds or those that go straight back to inventory.

The presetting station can download preset data with all of the known parameters for each tool list. The cart shows up at the presetter with all of the necessary data, which can be stored on a central server. Machine operators can also access the data, or some machine controllers can accept the data directly from the server. The operator simply pulls the part up on the machine and all the data is already available to him.

Legacy data is another advantage. If a tooling supplier pulls a tool from its lineup after a shop has been using it for a number of jobs over an extended period of time, the shop could feel the effects of the transition for a while. But with TDM, the operator can quickly search and access every job for which that tool was used and go through a process that will replace the tool with the new tool and tool data. “This simple search and replace capability is great for jobs that often require rework,” Mr. Rezny says. “If a job comes back in, you have a very good thumbprint of what was used and how it was done.”

The software allows tool data to be created, adjusted to needs and stored for access by all users. The data remains consistent throughout the entire process for increased part accuracy (and quality) and less time and effort in data management.

When it comes to software, savings are not always immediately apparent. Time savings are more difficult to quantify and often do not show up directly on the bottom line. But Mr. Rezny explains, “With employees trying to do more tasks than ever, this software becomes a vehicle for efficiency.” It’s this efficiency that should be considered in determining the payback in dollars and cents.

RELATED CONTENT

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

-

From Setup to Final Pass: CNC Tool Management

With today’s high-powered and graphic-intense CNC, operators have everything under control, all on one screen.