Heat’s Impact on Parts Cleaning

Appears in Print as: 'Bringing on the Heat in Parts Cleaning'

Thermal dynamics is important for assisting in the cleaning of a part. Adding heat or energy influences the cleaning process through its impact on chemistry, the water within the washer and its effect on drying.

#techbrief

Machine shops and manufacturers use cleaning technology to remove contaminants (including oils, metalworking fluids, grease, metal fines and even fingerprints) from parts and/or remove rust or other surface compounds left on parts from a prior operation. Adding to the complexity is that “clean” is a relative term. What might pass quality control in one operation might not for a different application. Once how “clean is clean” has been defined for an application, then the next challenge is determining the most cost-effective method(s) to achieve it.

And, in some cases, heat can play a significant role in the chosen parts cleaning process.

Thermal dynamics plays into the process of cleaning a part, but its effect is sometimes misunderstood. That’s because adding heat or energy influences the cleaning process through their impact on chemistry, the water within the washer and their effect on drying.

How Heat Affects Chemistry

Time, temperature, pressure, agitation and chemistry are all critical elements of successful parts cleaning. Basic thermodynamics tells us that all organic

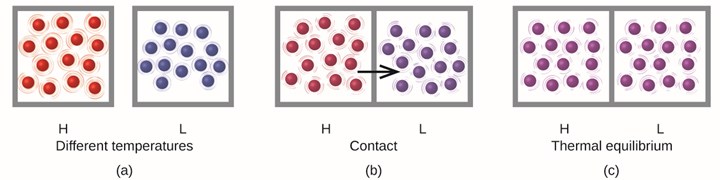

This chart shows that color change reflects the heat transferring from a hot matter (red dots) to cold matter (blue dots) until thermal equilibrium is achieved. This is how room temperature occurs. Photo credits: Trimac Industrial Systems.

matter desires to be at the same temperature. For example, a bucket of hot water in a cold room, given time, will eventually be the same temperature as the room because the water’s heat transfers its energy to the room’s air. This heat transfer happens because the molecules of the hotter matter (water) are moving faster than the cooler matter (air). The energy of the hotter movement is transferred through radiation, conduction of convection to the cooler molecules, inciting them to move more as they absorb the heat.

Heat is a form of energy. The addition of heat to a system speeds chemical reactions and interactions based on the laws of physics and chemistry. For parts washing processes, adding energy through heat to a cleaning operation offers many benefits. First, every 17°F increase in temperature can double reaction rates, which can drastically accelerate the process. Second, heat

Heat improves the cleaning process because hotter or faster moving water molecules do a better job of cleaning than slower moving molecules because the surface tension is reduced.

improves the cleaning process itself, thereby reducing the amount of chemistry required to do the same work. However, the level of heat also affects the chemistry. Not enough heat can cause chemistry foaming, and too much or improperly managed stack temperature can damage pumps or create acid rain. A well-designed parts washer will manage these issues and keep the operating tank temperature at an optimal 120° to 160°F, depending on the requirements of the chemistry and the bonding of the contaminants to the substrate.

Heat improves the cleaning process because hotter or faster moving water molecules do a better job cleaning than slower moving molecules because the surface tension is reduced. When this happens, the process displaces the dirt for the water to remove through the spray or immersion action. When washing, the soap molecules attach to the oils on a part, enabling water to seep in underneath. The particle of oil is then pried loose and surrounded by soap molecules to be carried off by the spray water.

How Heat Affects Spraying

Heating the water in a cleaning process not only improves cleaning results but also reduces the water pressure that is needed to dislodge dirt and contaminants. However, spraying that water has its own challenges. First, the water in the tank must be heated. Depending on the tank size, this can be done through electric elements or by using a gas burner, which typically involves an immersion tube or an external heat exchanger. The goal is to quickly heat the water with the ability to maintain the temperature. Conduction transfers the heat from the water to the physical tank itself. Heat loss from the tank walls to the exterior air needs to be taken into account. This loss can be minimized by insulating the exterior tank walls, but the return on investment will be unique to each project.

Water is sprayed on the dirty parts to clean them. Regardless of the washer design, once the water is sprayed, it is atomized. Once water is atomized through the spraying process, the surface area of the water is significantly increased. When this occurs, the rate of evaporation increases with the surface area ratio. Adding heat to the water further increases the evaporation rate as the water is exposed to the cooler air through the spraying process. Spray washers will have some type of walls to contain the spray. When the sprayed water comes into contact with the cooler washer walls and the parts themselves, that process also reduces the water temperature.

Although these heat loss effects cannot be prevented, they can be accommodated in the washer design. As the sprayed water is returned back to the tank, it is reheated to keep it at a constant temperature for optimum process control. Insulation can reduce the heat loss process, but it is an equipment investment decision compared to the utility consumption of heating the water. Insulating the water tank will provide the best economic and heat containment benefit followed by insulating the cabinet walls.

Air knives are the easiest way to move large amounts of water that gravity does not remove, but if that does not dry parts well enough, then a regenerative blower can be implemented. This will add about 40°F of heat to accelerate the process.

How Heat Affects Drying

After a parts washer has completed the cleaning step, a wet part is the result. To accelerate the drying process, air movement and heat should be present. Trapped and pooling water can best be removed through a targeted airflow. Air knives are the easiest way to move large amounts of water that gravity does not remove, but, if that does not dry parts well enough, then a regenerative blower can be implemented. This will add about 40°F of heat to accelerate the process. Even more heat can be added to the blower, if faster drying is needed. An oven can also be used with either convection or infrared processes to speed the drying process.

Working with an experienced parts washer original equipment manufacturer will ensure optimum design and performance for a particular application. If a part or process is unique, most manufacturers can perform testing to ensure an outcome to certain specifications. Depending on its construction of mild or stainless steel, a well-designed parts washer should last a minimum of 15 years to boost return on investment while meeting customers’ specifications for part cleanliness.

Trimac Industial Systems LLC | trimacsystems.com | 913-441-0043

About the Author

Marty Sawyer is the CEO of Trimac Industrial Systems, LLC. Trimac manufactures the Kemac brand of washers. Call 800-830-5112.

RELATED CONTENT

-

Getting Ready for Lights-Out Manufacturing

Lights-out manufacturing has the potential to save money while increasing capacity, but shops need the right equipment and to address potential challenges before implementing it.

-

Exploring the Benefits of Reaming for Finishing Bores

How does reaming compare to single-point boring? A supplier of reaming tools compares these processes commonly used to finish bores and offers tips for those considering reaming.

-

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.