Meet “Thunderdome.” Total cycle time to complete machining of the 27 contoured parts clamped in this custom fixture on a five-axis machine is six hours. (Photo Credits: Powill Manufacturing and Engineering)

Sometimes you have to have a little fun in our sometimes too serious world of machining precision parts.

Case in point: “Thunderdome.”

Featured Content

Thunderdome is the name given to the custom, dome-like fixture created by Powill Manufacturing and Engineering, one of a number of fixtures it has made since purchasing its first five-axis machine in 2011 to best make use of the machine’s integral B- and C-axis rotary tables.

Initially, though, the Phoenix, Arizona, shop used risers to lift parts clamped in conventional vises and three-jaw chucks up and away from the surface of the machine’s nearly 20-inch-diameter, C-axis table to provide the spindle and tool with better access to those parts when they were oriented at odd angles. It then began using commercially available workholding devices designed specifically for five-axis machines, which clamp on small dovetail profiles machined on the bottoms of workpiece blanks. These dovetail fixtures provide sufficient holding force for heavy cutting as well as ample clearance around the part. The shop still uses them today.

In some cases, however, even those devices are not the most effective workholding for the five-axis machine.

Powill came to realize the value that custom fixtures designed and manufactured in-house offer for certain jobs, primarily those involving tight-feature, true-position tolerances and/or large batch sizes. For the latter, the shop tries to create fixtures that can hold multiple parts to maximize spindle uptime as well as unattended machining time. Other custom fixtures hold parts that are highly contoured or otherwise cannot be held effectively using conventional workholding devices. The shop’s leadership feels these applications justify the time and cost required to develop such one-off workholding devices.

Powill has made a variety of custom fixtures for its five-axis machine. This article highlights two. The first is Thunderdome, which holds 27 parts and was dedicated to one complex, high-volume job. The second is a four-post fixture that holds four parts at once. Common dovetail-clamping interfaces maximized the return on investment in this fixture by making it useful for different jobs or part families.

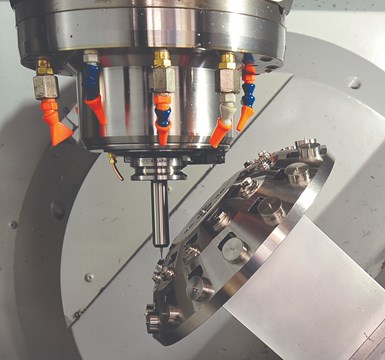

The dome-like shape of this fixture enabled the shop to secure all 27 parts on it at once, as well as provide clearance for cutting tools and the machine’s spindle.

Foray into Five Axis

Powill — which primarily serves the commercial and military aerospace industries — has CNC machines, including vertical machining centers (VMCs); horizontal machining centers (HMCs); a 40-inch-table vertical turning lathe (VTL); multitasking lathes; and grinding, honing and gundrilling machines. A high percentage of its business is job shop-type work, although it has some repeating contracts.

Kevin Wolfe is the company’s general manager. Wolfe says the primary reason the shop added its five-axis NMV5000 from DMG MORI was to reduce setups by enabling the spindle to access five sides of a part in one clamping. This is commonly known as 3+2 machining. The shop was also drawn to full five-axis contouring capability, although only a portion of the parts that run across that machine require that technique.

He says another feature that attracted the shop was the rigidity of the NMV5000’s B- and C-axis table-in-table design. The machine provides B-axis rotation of +160 to -180 degrees and 360 degrees of C-axis rotation, and maximum table load capacity is 661 pounds. It also features a more open design than trunnion tables that support the C-axis table at two locations, and parts can be flipped upside down to access features close to their base. In this case, chips fall harmlessly away rather than being recut, which can reduce tool life and mar surface finish. The ability to position parts at odd angles enables the use of shorter, more rigid tools that can take more aggressive cuts, too.

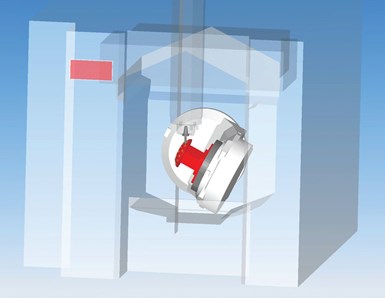

The machine came with a seat of Esprit Cam CAD/CAM software. Although learning this new software took time, part program simulation has proven valuable. The software was preloaded with a CAD model of the NMV5000 machine and all its primary moving components. To simulate machining operations for a job, CAD/CAM programmers simply add CAD models of the fixturing devices and workpiece to the machine model. Simulating the operation identifies possible interference points between spindle, cutters, fixtures or parts, so those issues can be fixed prior to running the job on the machine.

Another helpful five-axis programming feature is Composite Milling five-axis, which provides multiple machining patterns and tool-axis orientations to control all axes simultaneously for complex parts. ProfitMilling tool paths are particularly useful for Z-axis roughing of cylindrical floors, Wolfe adds. This strategy is designed to improve tool life and cycle time by optimizing tool engagement angles and chip loads.

The CAD/CAM software that came with the shop’s five-axis machine was loaded with a CAD model of that specific machine. Programmers can then easily add CAD models of fixtures and parts to perform part program simulation to ensure there will be no crashes or interferences with parts oriented at odd angles.

On to Thunderdome

A job with a batch size of 1,000 complex, contoured parts made from Inconel 625 led the shop to create a fixture that could accommodate 27 workpieces. In fact, the fixture was machined on the NMV5000.

The shop initially tried to fit as many parts as possible onto a rectangular fixture. The challenge with this type of prismatic fixturing concept was providing adequate clearance around each part for all the five-axis contouring operations. (Once complete, there are no straight sides on this part.) Unfortunately, this preliminary fixture design could only hold a maximum of 10 parts.

Wolfe thought that a dome-like-fixture shape might be able to accommodate more parts. Arranging them around a spherical profile might provide adequate access, while enabling more to be clamped at once. The resulting fixture was created from spare steel material the shop had on hand and was mounted on top of a rectangular riser. Someone jokingly said it looked like the Thunderdome arena from the “Mad Max Beyond Thunderdome” movie, and the nickname stuck.

“The shop tries to create fixtures that can hold multiple parts to maximize spindle uptime as well as unattended machining time.”

One challenge was determining how best to hold the blanks in this fixture. After all, it made sense to start with round stock that was closer to the part’s net shape. To do that, flats are machined in each blank to enable cam-actuated clamps from Mitee Bite to grip them. Two pockets were machined for each part, one for the clamping device and one for the round stock.

There are other challenges in creating such a fixture to hold multiple parts. For example, the parts must be spaced far enough apart and positioned in such a way as to provide adequate clearance around each. In addition, a balance must be struck between the number of parts a fixture will hold and overall fixture rigidity. Removing too much material to accommodate a large number of parts can limit both rigidity and how aggressively (how fast) those parts can be machined.

Thunderdome was designed to hold parts in two rows. Offsetting these rows of pockets enabled fitting a few more pockets on the lower row (15 parts, compared to 12 on the upper row). Total cycle time to machine all 27 clamped parts is six hours. After that, parts are mounted in custom vise jaws on a VMC that machines the bottom face and countersinks the back side of a through hole.

This fixture features four posts with their tops angled at 45 degrees. This provides sufficient spacing and clearance around parts when they are installed in the dovetail clamps that top the posts.

Alternately, a four-post fixture the shop created features an aluminum base with four steel posts, each with a dovetail interface that makes the fixture useful for a variety of different jobs. This versatility helped justify the time and cost of making the fixture in the first place.

However, the fixture’s first purpose was to help get started as quickly as possible on one particular job: a fuel block machined from a billet of 1215 steel with batch order quantities upwards of 300 parts. This large batch size was the primary reason why the shop considered a custom fixture that could mount multiple parts at once.

The fixture needed to be rigid enough to handle rough-milling work, but still provide the clearance necessary for engraving operations and drilling compound-angle holes toward the bottom of the part. The top of each post

This custom fixture that the shop created for its five-axis machine provides clearance for the tool and spindle to access the parts.

was machined at a 45-degree angle to extend workpieces out and away from one another and provide the tool clearance necessary to access all five faces of each part. The simulation capability and collision avoidance feature in the CAD/CAM software came in handy to ensure adequate clearance.

Workpiece blanks are first prepped on a VMC, which machines dovetail profiles on the face that requires the least amount of machining work (or none at all). Once the blanks are secured on the fixture, the cycle time to machine the four fuel blocks (sans removing the dovetail profile and performing additional machining on that sixth face) is 2.5 hours. For certain features, the machine’s B-axis table is tilted 135 degrees to reach features near the bottom of the parts. The dovetail profiles are subsequently milled away on an HMC, which also machines four holes that intersect the ports created on the five-axis machine. Completing this part on one of the shop’s HMCs would have required three separate operations and at least one custom fixture. Powill has subsequently used this fixture for a variety of other parts.

Prior to installing this fuel-block blank into the four-post fixture on the five-axis machine, the dovetail feature and associated pin slot are machined on a VMC. The shop says this configuration eliminates part movement, even during heavy roughing operations. The pin slot also locates the blank into the proper position in the dovetail fixture for repeatability. These features are milled away after work on the five-axis machine is completed (this is shown here halfway machined away).

Back in Time

In addition to creating custom fixtures for new jobs, Powill has used its workholding expertise to transfer jobs previously machined on three-axis equipment to the five-axis machine. The shop has also written programs to run other parts on the flexible four-post fixture. Consolidating multiple setups to produce parts in one clamping on the five-axis machine not only reduces production time but also improves part accuracy. In fact, Powill also uses its five-axis machine to create more accurate fixtures for its three-axis equipment because it can machine critical fixture-locating features in a single setup more precisely.

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Hard Turning as an Alternative to Grinding

Hard turning can be a cost effective alternative for shops looking to streamline part processing.

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.