Craftsman Cribsheet No. 121: ISO Turning — What Does it All Mean?

How to make sense of all those different letters and numbers in ISO turning inserts.

#pmpa

When it comes to ISO turning inserts, there is a lot of confusion about what all those different letters and numbers mean. We have CNMG, TNMG and WNMG. Then there is 432, 332, 434 and more. Even among those who deal with ISO turning inserts everyday, few know what all the different characters mean in relation to the insert. Also, we find that metric and inch standards differ. We discuss inch inserts in this article. Let’s use a CNMG 432 as an example.

CNMG

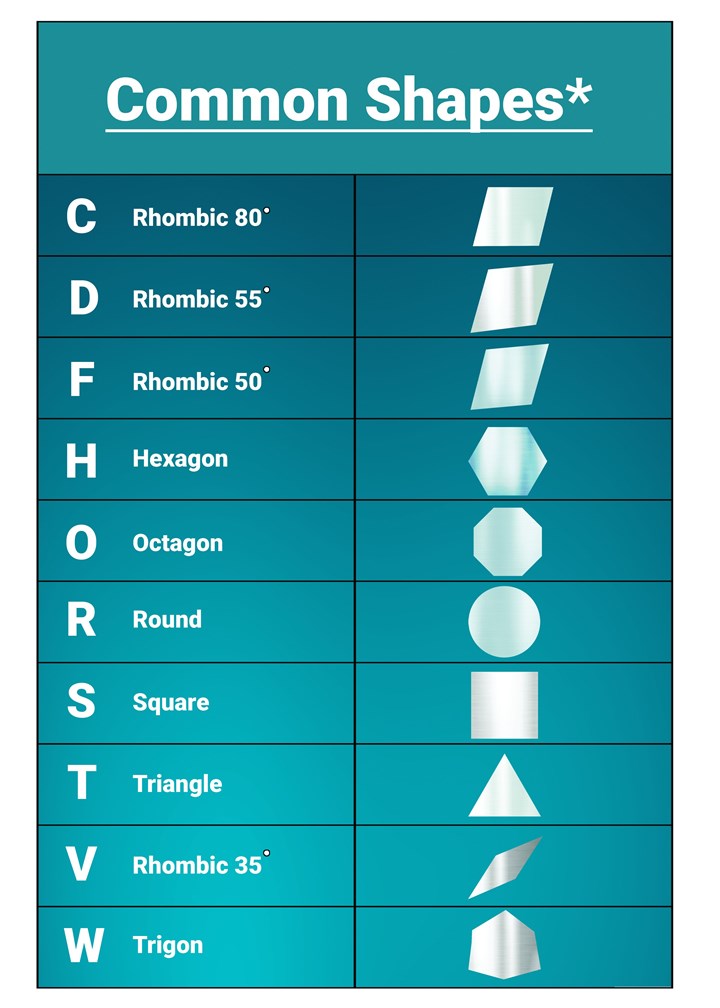

The first letter denotes the shape of the insert. Inserts come in a wide variety of shapes. In this example, “C” is an 80-degree rhombic shape. Other common shapes used in everyday machining include “T” Triangle, “W” Trigon and “V” 35-degrees rhombic.

Featured Content

CNMG

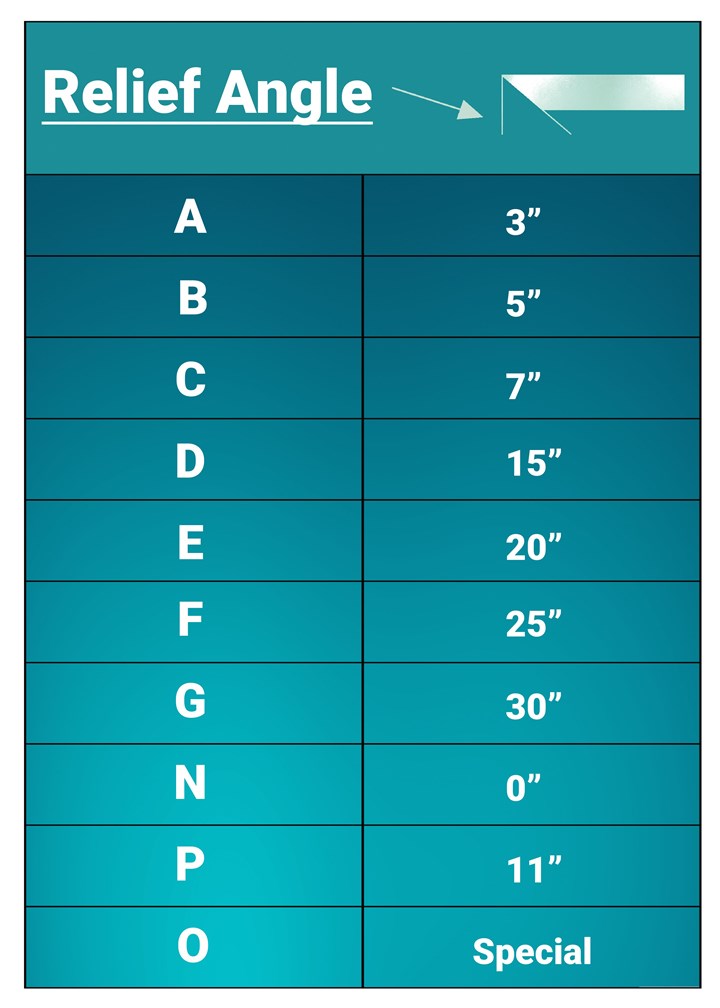

The second letter denotes relief angle. “N” in our example is a 0-degree relief angle. Angles can range from 3-degrees to 30-degrees on standards. Then there is the “O” designation or special angles. For front relief, “C” (7-degrees) is a good common angle for most materials. Some copper grades like to have a little more.

CNMG

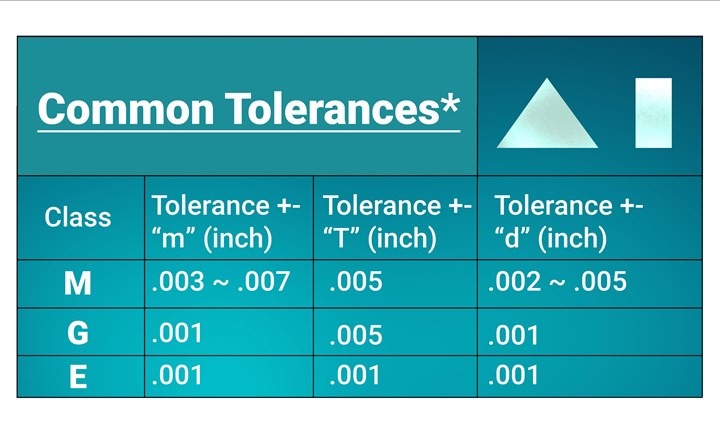

The third letter denotes tolerance level of the insert. The letter “m” is the tolerance of the cutting tip to the inscribed circle. “T” is the insert thickness tolerance. The letter “d” represents the inscribed circle tolerance. “M” is a common tolerance class. “G” is also a common tolerance class, but it comes at a higher cost per insert because of the much better tolerances.

CNMG

The fourth letter denotes fixing and chip breaking. “G” is put in with a screw with no special chamfers on the insert. The chip breaking part was a good idea, but in practice does not really matter.

Most manufacturers make custom or patented chip breakers that have nothing to do with this designation. This letter usually only indicates how the insert attaches to the holder and the back rake design.

The Numbers

432

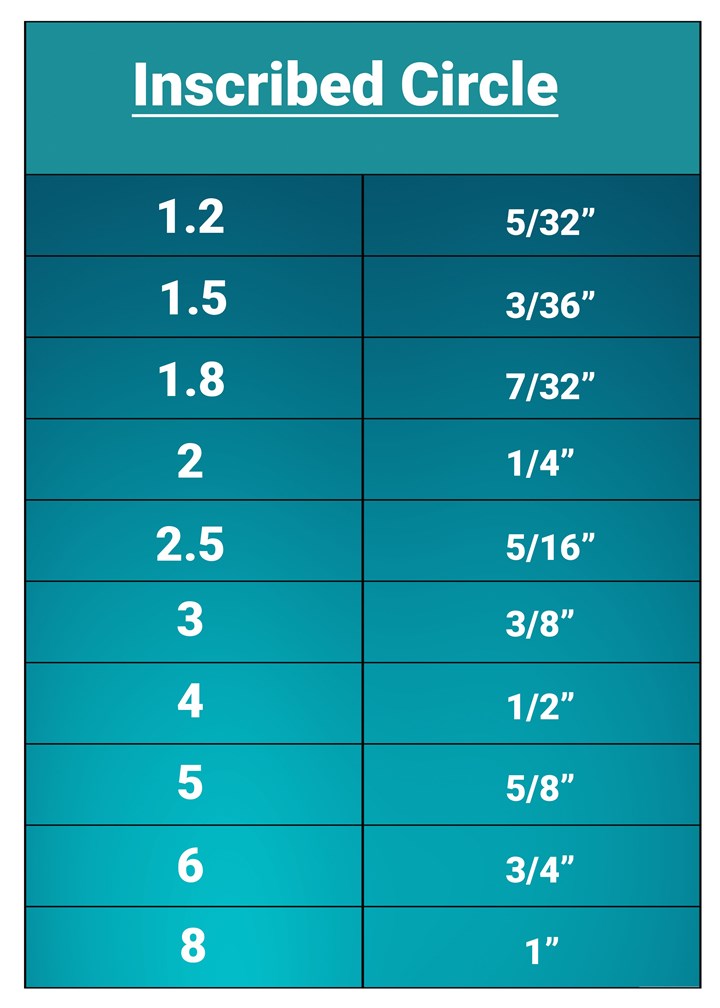

The first number denotes the inscribed circle of the insert. In the example, “4” indicates a 1/2" inscribed circle.

432

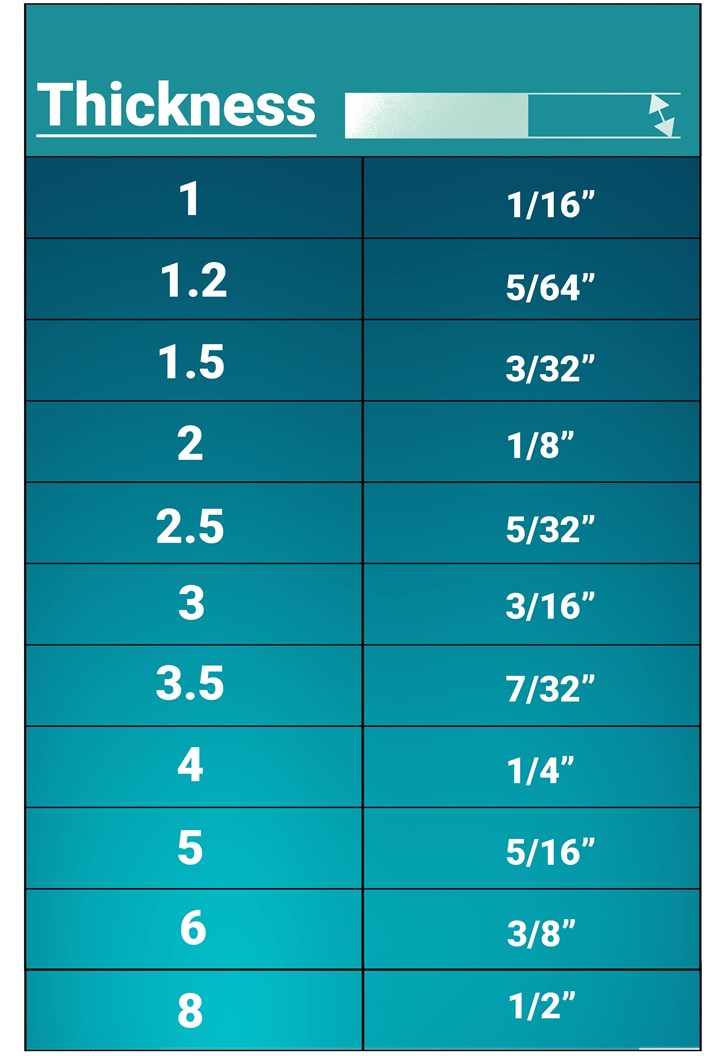

The second number indicates the thickness of the insert. In this example, “3” indicates 3/16" thick.

432

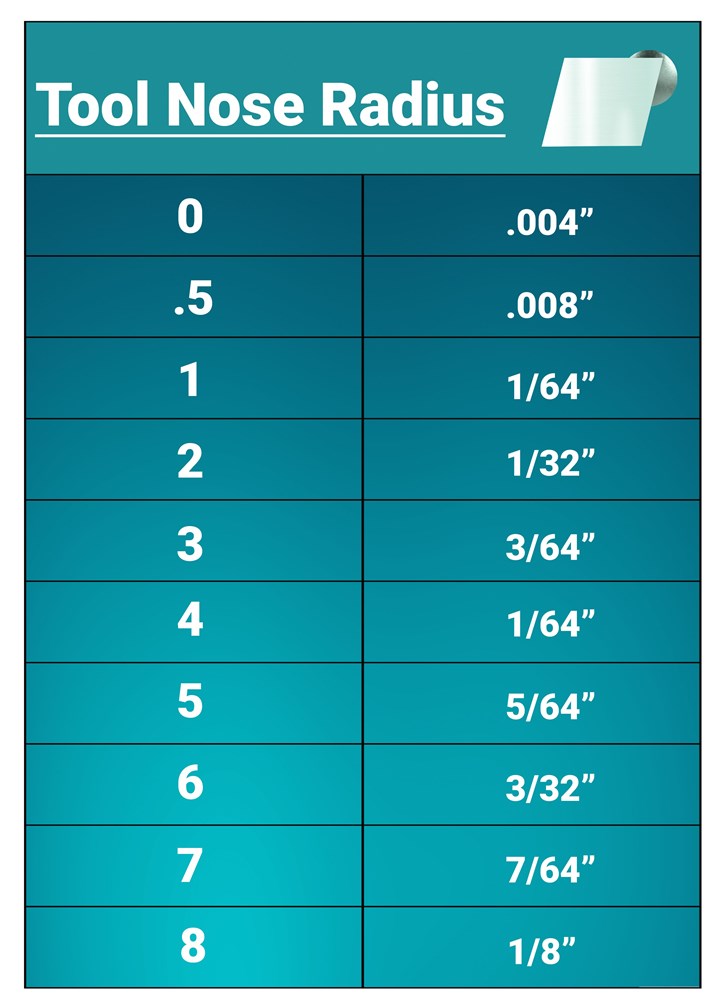

The third number indicates the tool nose radius of the insert. In this example, “2” indicates 1/32"(0.031")

-XX

After the third number is the reserve space for the manufacturer’s chip breaker. Some manufacturers use this space; others do not. It is not limited to two characters. Some manufacturers use combinations of letters and numbers.

*Note tables referencing common are not complete datasets but a listing of commonly used standards.

About the Author

David Wynn

David Wynn, MBA, is the PMPA Technical Services Manager with over 20 years of experience in the areas of manufacturing, quality, ownership, IT and economics.

Email: dwynn@pmpa.org — Website: pmpa.org.

RELATED CONTENT

-

Steel Defects Seams on Rolled Steel Products

Learn how to detect and avoid defect seams in rolled steel products.

-

Rapid Methods for Determining the Weight of a Steel Bar (Imperial Units)

Counting bars in a bundle and multiplying by weight per bar allows a quick “reality check” on whether or not the tag weight is correct, or how much weight is left in the rack.

-

Steel Defects Slivers on Rolled Steel Products

Steel defects slivers are, by their very nature, “injurious defects,” and as such rejectable.