Cleaning Parts Cost Effectively

A shop should look at all aspects of the production process to maximize productivity. This includes selecting an efficient cleaning system.

Successful manufacturers understand the importance of improving part-making processes to increase productivity and, therefore, be more competitive and profitable. However, they sometimes focus on the obvious issues, such as decreasing CNC machine cycle times, rather than considering the bigger picture. Maximizing productivity means looking at the entire manufacturing process from raw materials to finished product, and making each step along the way as efficient as possible. This macro view includes making sure the parts that are shipped comply with the cleanliness requirements of the customer, whether the parts are in finished form or moving on to another process, such as coating or plating.

In the case of parts with simple geometry, manufactured using water-soluble coolant, a basic aqueous solution bath or rinse may be all that is necessary. However, more complex parts machined using cutting oils, including those with blind holes, cross-holes and ID threads, may require a more sophisticated cleaning process. And because water-based cleaning solution rinses are not always capable of adequately removing debris and oil-based residue from these parts, solvent-based cleaning agents may need to be employed. Using this process raises environmental issues and the need to adhere to federal and state mandates regarding the use and disposal of these chemicals.

Yet another consideration is the number and types of parts being produced. A variety of parts for various customers may require different kinds of cleaning. Because such an array of influential factors is involved, efficient, cost effective parts cleaning processes may be a bit more complex than expected.

Part Cleaning Basics

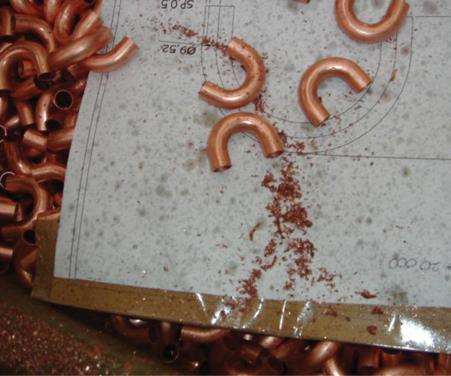

Almost all parts coming out of a turning or machining center are coated with the residue of either aquebased or oil-based cutting fluids and are covered with some amount of swarf. Depending on the next step in the part’s life, a specific amount of cleaning is in order. A major factor in determining the type of cleaning necessary is the degree of cleanliness specified by the customer. If the part is to be plated or coated, for example, it must be clean enough for the coating or plating to properly adhere to the surface. Other issues to consider include the part material, the nature of the debris to be removed and whether the part has simple or complex geometry.

Parts cleaning methods include the use of water-based or solvent-based chemicals, and within those two categories are a number of variables. With water-based products, the degree of pH in the detergent should be matched to the metal involved. High alkaline solutions can etch or discolor soft materials, while hard metals may need a high pH to effectively remove coolant residue. Additionally, using unfiltered water to clean parts can introduce unwanted minerals and other contaminants that may inhibit the cleaning process or even damage part finishes.

Solvent-based chemicals may be the only way to thoroughly clean parts that have been machined in oil-based coolants, have complex geometry or are made from metals that don’t react well with aqueous solutions. Although the EPA and other state agencies have a history of discouraging the use of solvents, they have recently realized that, when used properly, hydrocarbon and modified alcohol solvents are the chemicals of choice for many parts cleaning operations.

In addition to determining the appropriate chemical properties of the cleaning solution, effectively cleansing some parts may require mechanical action such as high-pressure sprays, agitating the chemical bath or rotating the basket within a cleaning chamber.

Ultrasound is another method used to break loose contaminants. These high frequencies, well above the threshold of human hearing, produce thousands of tiny bubbles that implode when they strike the surface of a part. The energy released by this action gently removes contaminants from the part.

Because the air in a manufacturing environment may contain dust, cutting oils or other residue, it’s important to keep these additional contaminants from the parts cleaning environment. In some cases, filtering may help, but the more effective method is to vacuum air out of the cleaning chamber and clean the parts in a sealed environment.

An even more important benefit of using a vacuum process is that it removes air pockets from the complex part features to allow the solvents to clean more effectively. Moreover, solvent used in a vacuum has a lower boiling point, so the overall temperature in the cleaning area is reduced. This puts less stress on the solvent, thus enabling its reuse.

Safe Solvent-Based Cleaning

Thoroughly cleaning complex machined parts in a reasonable period of time, especially those with such features as ID threads, blind holes and cross holes, is typically beyond the capabilities of aqueous-based cleaning systems. Yet cleaning with solvents is potentially harmful to both workers and the environment. That’s why it’s important to use a parts cleaning system that not only handles the toughest parts cleaning challenges, but also prevents the solvents used from impacting the workplace and overall environment.

Gosiger offers the iFP Kleen Power vacuum parts washer as a solution for a range of parts cleaning applications. These programmable systems clean baskets of parts in a sealed chamber using hydrocarbons or modified alcohol-based solutions that are internally recycled through a distillation process, so the environment is protected and users save money by recapturing and reusing the cleaning solutions.

Because different parts present a variety of cleaning challenges, the Kleen Power system incorporates spraying, immersion, submerged jets, ultrasonic and vapor cleaning options. These variables can be applied either statically or with oscillation or rotation added.

Establishing the correct combination of cleaning factors is essential to maximizing efficiency. The goal is to establish a process with the shortest cycle time that will effectively clean the parts. Parts requiring a light amount of cleaning may simply need to soak in solvent for a specified period of time and nothing more. On the other hand, complex parts may require a combination of agitation, ultrasound and spraying to get the many facets of the part thoroughly clean and satisfy the customer’s requirements. In addition, some metals require protection from rust, so the system is also capable of applying a rust-inhibiting agent when the parts are completely clean.

Once the most efficient cleaning regimen is established for a specific part, it can be assigned a program reference number that is stored in the Kleen Power controller for future use. Each time a batch of corresponding parts is ready for cleaning, the operator simply enters the program number and starts the machine. Operators can save additional programming time by starting with the parameters of an existing program and making modifications for a different part and storing the new program.

In Operation

The setup process for the Kleen Power system is relatively simple. An operator manually loads parts into a basket, places the basket into the cleaning chamber and closes the door. Optionally, an automation system using a conveying device can feed the basket into the chamber and the chamber door closes.

Once the chamber door is sealed, a pump pulls the air out of the chamber to create a vacuum. The chamber is then filled with the appropriate solvent. The part-specific program dictates which cleaning actions will be employed, as well as the sequence and time intervals of each operation.

Upon completion of the cleaning cycle, the solvent is drained from the chamber and the system creates a vacuum to remove all remaining fluids and residue to leave the parts completely clean. If desired, a separate tank will apply a rust preventive solution to the parts. The recaptured solvent is distilled and internally recycled for future use.

Cost Savings

In addition to the savings realized by recapturing and reusing cleaning solutions, the Kleen Power vacuum parts washer eliminates the costs associated with disposing of spent solvents or aqueous cleaning solutions containing the oil and other contaminants removed from the parts. Other savings include the labor involved in sorting parts that are not adequately cleaned during less thorough processes and the ability to clean batches of parts or run the system’s distillation process overnight.

These systems also include remote diagnostics that allow Gosiger technicians to help customers tweak cleaning programs for new parts in real time.