Depending on the source of data, forecasters predict the medical manufacturing segment will grow at an annual rate of between 5% and 8% over the next seven years. It’s of no surprise that many shops seeking sources of stability in an unpredictable market are looking to add or increase the share of medical work within their portfolio of business.

Moving into medical manufacturing brings with it a unique mix of challenges. With very few exceptions, medical parts tend to be small, as the vast majority are used as either implants or instruments to operate on the human body. Accuracy, precision and surface finish all take on extreme importance, as compromises can directly impact a patient’s life or quality of life.

While stainless steel is often used for surgical instruments, difficult-to-machine, exotic materials are the norm for implants. These include cobalt chrome, titanium alloys, ultra high molecular weight polyethylene (UHMWPE) and polyether ether ketone (PEEK), each of which brings its own set of considerations. Selecting the appropriate mix of machine and tooling for each application becomes extremely important.

Additionally, the FDA regulates manufacturing processes for medical devices and implants. For those considering moving into the segment, this presents both a barrier to entry and opportunity. On one hand, it is a complicated process that can be daunting to complete. While that can be intimidating to newcomers, it also can lead to stagnation from manufacturers already in the field, as changing processes can be cumbersome. This can provide an advantage to new entrants who are validating processes that incorporate the latest innovations in machines and tools.

Whether a company is making an initial move into medical manufacturing or looking to update and validate production of an existing part, machine selection plays a vital role. By focusing on four fairly typical real-world components that are currently optimized on four distinct machines, we can gain insight into how choosing the right machine can help ensure success.

Hip Cup Production on a Turn Mill

Usually measuring approximately 2" in diameter by 1" in height, a hip cup is the portion of an artificial hip that is implanted into the pelvis. Resembling a half-sphere and frequently machined from cobalt chrome, the part requires high accuracy and an exterior surface finish that will promulgate integration with bone tissue.

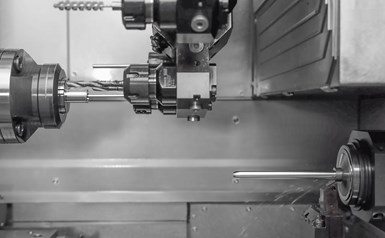

The geometry of a hip cup requires a flexible machine, while the nature of cobalt chrome necessitates robust performance. A CNC turn mill offers the ideal mix of features. In particular, INDEX recommends our G200 turn mill.

In this application, the G200’s identical, powerful main and counter spindles provide the balance needed to productively machine the part’s interior and exterior. By applying three tool carriers, each with a Y axis, the manufacturer is able to achieve maximum material removal rates. Furthermore, the machine’s milling spindle incorporates a 360-degree B axis that enables efficient machining of features needed to ensure the part’s functionality. A typical hip cup machined on a G200 would have a cycle time in the neighborhood of 12 minutes.

Bone Nail Production on a Sliding Headstock Lathe

Bone nails are often used to treat fractures of one of the long bones in an arm or leg. Machined from titanium and titanium alloys, they are driven through the center of the bone to permanently reside in the bone marrow. Screws are then driven through both the bone and nail to provide rotational stability, resulting in an implant that provides strength to reinforce the bone and allow it to heal.

Bone nails can be as narrow as 0.35" in diameter, but commonly require lengths of up to 12". Because of the high length-to-diameter ratio, a sliding headstock, or Swiss-type, lathe is the only suitable solution for these components. Among INDEX machines, our TNL32 is ideal because of its maximum Z-axis travel of up to 11.8".

While sliding headstocks lathes traditionally have used gang-style tooling, the TNL Series uses turrets, which provides especially advantageous for bone nails. The machine can put three tools into the cut simultaneously to maximize productivity, while the inclusion of a B axis in the upper turret allows for efficient machining of these parts’ inclined holes and surfaces. Cycle times on the TNL32 vary by part length, but as an example, a medical manufacturer running 8.66" bone nails on the machine is achieving a cycle time of 9 minutes 3 seconds.

Bone Screw Production on a Sliding Headstock Lathe

Used to secure a wide and diverse range of implants to bone tissue, bone screws vary significantly in their length, size and shape. Typically machined from titanium alloys, these components can be used to permanently or temporarily affix plates and rods to bones.

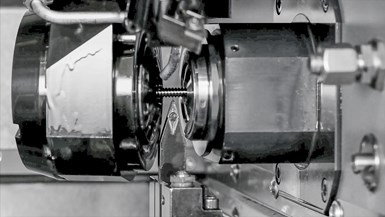

While the length-to-diameter ratio of bone screws fluctuates across parts, most fall above the 6:1 figure typically used as the benchmark at which traditional machining becomes impossible and a sliding headstock lathe is required. Among INDEX customers, the TNL20 is currently the most common machine used for producing these parts.

Many of the same features that make TNL machines ideal for bone nails also apply to bone screws. In particular, the range of tools available and robust live tooling capabilities prove especially beneficial when producing the hexagon, slot, torx and square profiles required by bone screws. The TNL20’s thread whirling ability also provides a competitive advantage by dramatically increasing productivity. Exact cycle times may vary by size and specification, but the pictured bone screw is machined in just 3 minutes 27 seconds.

Tulip Head Production on a CNC Multi-Spindle Lathe

When the vertebrae and discs of the spinal column are damaged, a pedicle screw system can be implanted to provide strength and support. One of the common components of this system is the polyaxial pedicle screw head, also known as a tulip head due to its geometry. These parts help surgeons guide and secure bone screws during surgery.

Measuring approximately 0.5" in both diameter and length, tulip heads are usually machined from titanium alloys and obviously have high accuracy and surface finish requirements. They require ID and OD turning, drilling of cross and through holes and interior threading. The size and range of features make them a perfect match to an MS22-8 CNC multi-spindle lathe.

With 8 spindles, 2 tool carriers per spindle and live tooling capabilities, the MS22-8 easily handles the level of complexity found in tulip heads. Each of the machine’s spindles is fluid-cooled and capable of independent speeds, further enhancing flexibility and ensuring accuracy. With this combination of part and machine, manufacturers can expect to achieve cycle times of approximately 60 seconds.

The Cost of Picking the Wrong Machine

Optimizing the production of medical components requires significant attention to selecting the best machine for the job. The previously mentioned tulip heads provide a dramatic example of this in action.

Many medical manufacturers can fall into the trap of thinking of their sliding headstock lathes as simply machines for small parts, as opposed to machines for small parts with high length-to-diameter ratios. In fact, a study conducted by INDEX found that over 40% of parts produced on sliding headstock lathes were below the ratio that requires that type of machine.

We worked with a tulip head manufacturer who was considering acquiring a new sliding headstock lathe to expand its capacity for producing that part. Below is a simplified version of an ROI comparison we help them prepare to evaluate whether to acquire a sliding headstock lathe or CNC multi-spindle.

|

CNC Multi-Spindle |

Sliding Headstock Lathe |

|

|

Initial Investment |

$2,100,000 |

$500,000 |

|

Finance period (months) |

84 |

84 |

|

Monthly payment (5.75% int.) |

$30,427 |

$7,245 |

|

Daily operating hours |

20 |

20 |

|

Cycle time (seconds) |

60 |

348 |

|

Pieces/week |

5,806 |

1,034 |

|

Pieces/year (50 weeks) |

290,323 |

51,724 |

|

Cost/piece |

$1.26 |

$1.68 |

Needless to say, they were surprised to see that their profitability could be increased by 34% by selecting the multi-spindle. Today, that has become their standard method for producing the family of parts.

When considering a machine investment to establish or expand medical manufacturing capacity, a company will be best served by selecting a machine tool partner with a broad range of machine types and the experience-based expertise needed to select which would be best suited to specific applications. INDEX has helped medical manufacturers around the world establish and maintain a profitable competitive advantage, and has engineers on hand who are glad to provide consultation on how best to address your current needs.