The need to reduce cost-per-part, improve productivity, manage product quality and gain competitive advantage drives manufacturers to examine all aspects of their production processes. For those who use turning machines to make parts out of barstock, employing modern bar feeders can have a major impact on achieving these goals, especially now that bar feeders have entered the age of the Industrial Internet of Things (IIoT).

For many years, loading barstock was purely a manual practice that slowed production and did little to maintain product quality. There was also a significant danger of injury to machine operators who could be hit by exposed barstock rotating at high speeds. In fact, early bar loaders were simply holding or guiding devices that limited spindle speeds, produced significant vibration and often damaged workpieces and machine tools.

In the years since, bar feeders evolved from principally mechanical devices into sophisticated systems that incorporate servomotors, absolute encoders and a variety of automatic, self-adjusting components. These advances—sometimes major steps forward, sometimes incremental—have steadily improved bar loading speed, support, safety and reliability. To provide the best solutions for a variety of applications, automatic bar feeders are now available in versions that accommodate 12-foot, 6-foot and spindle-length bars and operate with both fixed and sliding headstock (Swiss-type) turning machines.

The Ethernet Connection

One of the most dramatic leaps forward in bar-feed technology has been the incorporation of Ethernet connectivity to allow the bar feeder to bilaterally communicate with the CNC machine controller. This sharing of data provides manufacturers with a number of benefits, including reducing material waste and enabling on-the-fly, automatic change-overs of part programs.

Enabling machine tools to interconnect with other factory equipment has been a hot topic in manufacturing for the past few years. In some cases, forays into interconnectivity have had limited practical application. However, the e-Connect Ethernet communications system, developed by bar feeder maker LNS for interconnectivity between the bar feeder and the machine tool, is designed to provide real-world IIoT solutions for any size manufacturer, from high-volume production to small batch, mixed-parts runs.

Reducing Material and Labor Costs

For many shops, the cost of all barstock—especially materials such as titanium and exotic alloys—makes reducing waste an important consideration. Tossing away a remnant of these expensive materials is like throwing dollar bills into the scrap heap. With e-Connect, material usage is continuously monitored and communicated to the CNC machine control. When the shared data indicates that there is not enough material left to make the next part in a given run, the system scans the master production schedule to find another part in the queue that can be made from the remnant. When the part is identified, the machine tool and bar feeder automatically adjust to make the selected part or parts. Once the bar is used up, the bar feeder loads the next bar, and the system repeats the process until it makes all of the scheduled parts.

In addition to better material usage, there is also substantial labor cost savings because the change-over, within the diameter range, is performed without operator intervention. Fewer touches by the machine operator improves throughput, reduces the possibility of human error and allows one operator to tend multiple workstations. This level of automation—along with remote monitoring of bar feeder health—also makes unattended, lights-out production possible, even for batches of mixed parts.

To further augment lights-out production, the e-Connect system provides real-time monitoring of other LNS peripherals including chip conveyors, high-pressure systems, oil/mist collectors and other devices for worry-free overnight production. The data for all these devices flows through e-Connect, so there is no need for dedicated data lines from each product.

A Case in Point

An example of a CNC shop using this level of interconnectivity to reduce cost-per-part while meeting customer just-in-time delivery requirements is American Punch (Cleveland, Ohio). The company makes precision punches and dies for heavy gage applications such as bridge and truck frame components, as well as lighter gage parts for consumer products such as appliances and automotive parts.

As the company’s customers required smaller lots of 5, 10 or 20 pieces at a time, rather than high-volume runs, American Punch had to re-think its production processes. One approach was to continue to make long runs and stockpile the excess inventory for future deliveries. Although the company already stocked a number of high-turnover parts for certain customers, adding stocks of lower-volume parts would tie up additional working capital and floor space.

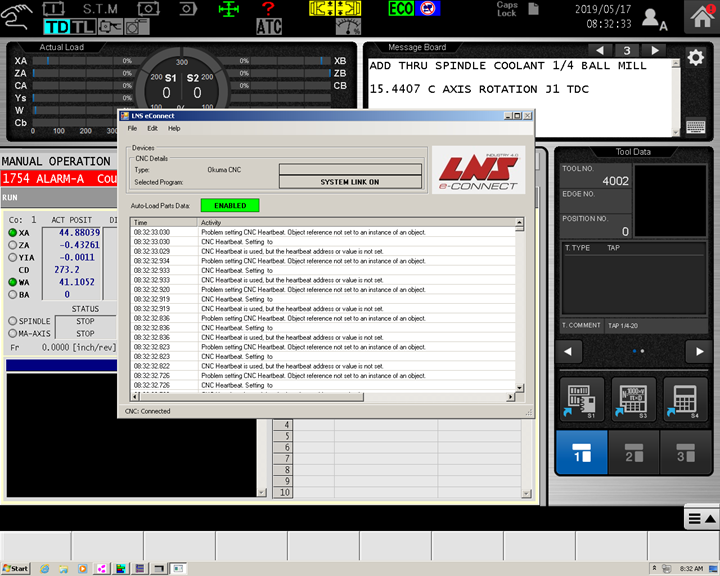

This work cell uses the LNS e-Connect Ethernet communications system, sharing data between the LNS Quick Load Servo 80 S2 automatic spindle-length bar feeder and the Doosan machining center’s master schedule.

A more appealing solution would be to somehow group together a family of similar parts that have a variety of lengths and run them all at the same time with a single setup. The e-Connect system makes this possible by communicating with the CNC machine’s onboard master production schedule. Once the machine tool completes a part run it examines the production schedule, selects the next part to be produced, and sends this data to the bar feeder. The bar feeder then consults its internal Part Library, in which all the parameters for hundreds of part programs are stored. Here, it finds the data for the program matching the one chosen by the CNC machine’s master schedule and automatically adjusts itself for the new part run.

In this installation, the e-Connect system resides in the LNS Quick Load Servo 80 S2 spindle-length, all-electric, servo-controlled, fully automatic bar feeder that loads 14-inch to 63-inch bars (not to exceed spindle length) with diameters ranging from ¼ inch to 3 1/8 inches. The machine operator loads the bar feeder with 1 ½-inch tool steel barstock and runs a macro program that enables the CNC machine control and bar feeder to change from one family of parts to another on the fly.

A typical setup would include loading the appropriate diameter barstock to make various quantities of different length parts. For example, using 1 1/2-inch diameter bars to produce 50 parts 2.500 inches long, 10 parts 3.025 inches long, 75 parts 3.500 inches long, and so on. The parts may vary in form, as well. Previously, the machine operator loaded the bars and stood by the machine as it made a small batch of parts. He then reset the CNC machine and the bar feeder to make the next size part. Now, the operator simply sets up the run, loads the barstock and starts the machines. As the work cell produces the entire mixed-parts run unattended, the operator is free to tend other work cells and perform additional tasks.

The company currently has four work cells that use the LNS e-Connect system and bar feeders to run over 300,000 parts each month. The newest work cell consists of an LNS Quick Load Servo 80 S2 bar feeder loading barstock into a turning center with milling, drilling and tapping capabilities. In addition to interfacing with the LNS bar feeder, the CNC machine also communicates with a ChipBlaster programmable, high-pressure system to apply the precise amount of coolant for each machining operation.

According to the company’s production engineer, “These work cells have made a significant improvement in our cost-per-part through unattended operation and by adding a labor-free overnight shift. Equally important has been the improvement in our ability to meet our customers’ delivery demands. Without the e-Connect system, we were constantly struggling to stay on top of orders. Now, we not only solved the time-to-delivery issue, we’ve expanded our capacity to take on additional work.”

Custom Solutions

A key component in the e-Connect system for bar feeders is the Parts Library function that holds hundreds of part programs and is more than adequate for most users. However, in some cases e-Connect can be easily customized for unusual applications. For example, in one situation a CNC shop runs thousands of a family of parts that are all the same diameter and shape, but vary in length from 2.5 inchs to 49 inches in 0.5-inch increments.

The LNS e-Connect display shows the current status of all data being exchanged between the LNS bar feeder and CNC machine tool. Data is continually updated for all connected LNS peripherals.

Typically, these programs would be loaded into the Parts Library, which will automatically adjust all the bar feeder parameters to comply with the machine tool program to be run. In this situation, because the only variable is the length of each part, e-Connect simply conveys only the appropriate length data directly to the bar feeder when changing from one part program to another. Since all the other parameters are the same, eliminating the need to access the entire part program data further streamlines the changeover process. Multiplying this time savings by thousands of parts has a significant impact on productivity.

Today & Tomorrow

Adding this level of interconnectivity to the many other benefits of bar feeders can make a substantial difference for any sized facility producing turned parts. It enables more profitable short runs and trouble-free high-volume production. In the future, interconnectivity of this kind coupled with Artificial Intelligence (AI) may open up even more opportunities for reducing time, material and labor costs.

American Punch |800-243-1492 |americanpunchco.com

RELATED CONTENT

-

Automation in High-Mix, Low-Volume Turning Applications

Turning shops are familiar with automation for high-volume work, but the shifting landscape to smaller batch sizes has created new challenges.

-

What Is The Best Bar Feed System For Production Turning?

Selecting the right bar feeder can be one of the most important decisions a shop can make. Bar feed systems help improve productivity, throughput and quality, but in order to achieve the most benefit from them it is essential that a bar feed system be matched to the particular needs of the turning operation.

-

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.