A Reflection on 50 Years in Manufacturing

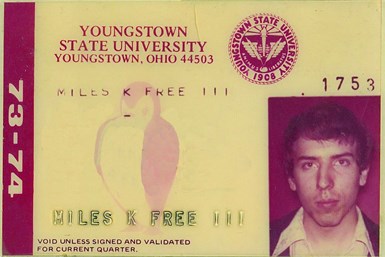

Miles Free III shares his stories and the lessons learned over 50 years in manufacturing.

#pmpa

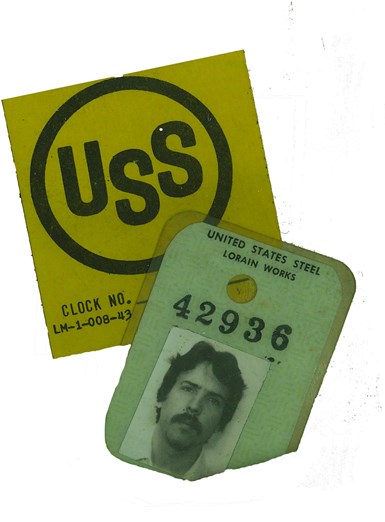

Last month marked the 50th anniversary of my full-time career in manufacturing. I had worked summer jobs in the steel mills prior, but on September 23, 1976, I became clock number 1906 at U.S. Steel’s Ohio Works, shoveling iron ore spillage as part of the labor gang in the sintering plant. The fact that you are reading this indicates that there is a happy ending to this story, but I thought that I would share some lessons I’ve learned during my

50 years in manufacturing.

Safety First

The steel plants in Youngstown, Ohio, were ancient and out of date by the 1970’s when I arrived. The sintering plant where I was hired was one of the newest facilities — and it was built in the 1940s. The rolling mills were steam-powered. For perspective, OSHA was formed just two years prior to my hire — on April 28, 1971. The respirators that we were issued to protect us from dust, radon and other chemicals weren’t OSHA approved; they were approved under the Mine Safety Administration. But safety was a formal and important aspect of our work there.

Featured Content

Literally everything in the sinter plant was lethal in some fashion: horsepower of the conveyor belts, toxicity of the dusts, contact with hot sinter, high voltage in the controls. Even the spillage we were shoveling was slippery and could cause you to fall into moving equipment. Guards were in place around everything, as were cable limit switches to affect an immediate disconnect of equipment to power.

Lesson learned — When everything around you can kill you, paying attention to safety is the first priority.

New Technology

I moved up to blast furnace burden clerk in 1976 where I had to prepare a daily report of the hot metal (iron) produced by our blast furnaces. It was arithmetic, how much did the ladle car weigh “empty” and how much after tap, and then weight of all cars summed for the day.

But to report this involved using a machine with a rotating drum to clip in the paper that connected to the handset of our dial telephone to transmit the report to corporate headquarters.

This machine — it was called a fax machine — required that a very soft pencil be used to assure maximum contrast and would take about three minutes to scan and send the document to the machine on the other end. This was an amazing labor savings compared to having to teletype the entire report, as was done previously.

Lesson learned — New technology is your friend and frees you up to do more valuable work.

Environment

I transferred to the Lorain Cuyahoga works in 1978 in anticipation of the Youngstown mills being closed. One of the reasons for the closing of the steel mills in Mahoning County was a new rule from a new agency called the EPA. The EPA was created by Richard Nixon on December 2, 1970, to protect human health and the environment.

The Clean Water Act of 1972 (actually a compendium of amendments to the 1948 Federal Water Pollution Control Act) sounded the death knell for the steel plants that discharged both thermal and chemical loads into the Mahoning River. The river — which had never frozen in winter in my family’s memory over three generations — was now being held to what was called a “cold water fishery standard.”

At Lorain, I started once again back in the labor gang, moved to mobile equipment operator, then department clerk, before getting a chance to go into environmental engineering. At Lorain, the Coke plant was threatened with shutdowns if we didn’t find a way to significantly reduce visible air emissions. I was part of the team created to develop and implement a new process called stage charging, and the emissions were brought to a level that allowed the coke plant to operate for many more years.

Lesson learned — Sustainability isn’t bad, but we have to manage for the greatest good, not the immediate and expedient outcome that we think we want.

Quality — Threat Becomes Opportunity

In 1984, I was among the 200 first-line supervisors and salaried personnel who were discharged due to competition from the Japanese steel makers making us redundant. We had just started corporate training on statistical process control (SPC) and I was pleased to have earned my certificates before the discharge notices came.

My immediate superior had arranged for me to interview for a job at a customer, and while I had a great interview, all hiring was on hold due to a corporate buy-out and restructuring. So, I attended community college for more coursework on machining, statistics, and quality control. When the hiring freeze thawed, I joined Bliss and Laughlin Steel and started implementing SPC at our Medina, Ohio, plant.

Success leads to success — that’s a lesson from manufacturing as well — and I was promoted to manager customer service at our newest plant, where I led our team to earn the first Ford Q-1 Quality Systems Award to be awarded to a non-integrated steel mill. We displaced the Japanese steel suppliers at the Ford plants that used our cold drawn steel bars, logging several consecutive years of zero PPM at many of our other automotive customers.

At that time, I was active on the PMPA’s Quality Committee, authoring white papers, and sharing and networking with others to help us all retool our management methods to better control and assure quality.

Lesson learned — Adversity is an opportunity for improvement, an opportunity for team work to get an important job done, and a chance for a career upgrade for all involved.

Lesson of Lessons — Manufacturing Is Really About Continuous Improvement

It’s been 50 years, and while I am now a staffer at a manufacturing association, I am still on the shop floor — virtually or in person almost every day. What U.S. material is equivalent to this European designation? How to clean steel bars that have been contaminated from improper storage? How to eliminate staining on plated parts? Why are my stainless-steel bars magnetic? These are the kinds of member questions I’m privileged to answer at PMPA.

In 50 years, I have come a long way from being paid for my labor and ability to lift a shovel full of iron ore or Coke breeze with an MSA-approved respirator over my face.

But this didn’t happen by accident. It happened — despite the circumstances, the plant closings, the lay-offs, and other uncontrollable situations — because of a vision to improve what I knew. To learn more. To apply it. And to commit to achieving my highest and best use. At one time, I just wanted to work in the laboratory. Well, I got to be the foreman of the laboratory. But manufacturing has a higher and better use for all of us — perhaps one we don’t even know that exists yet.

All we have to do is use our superpower. What is the superpower we have as manufacturers? Showing up. You cannot make a difference if you don’t show up. Just show up. Magic doesn’t happen sitting at home or idle on the street. It shows up when you are doing your job, and another opportunity beckons. A threat that needs to be overcome. You are the bench. Raise your hand. Do your very best. Learn and apply.

Lesson learned: Continuous improvement is the way of manufacturing. Improve and thrive. Show up. Learn. Improve. Succeed. May not be guaranteed, but after 50 years, it’s the way I’d bet on.

About the Author

Miles Free III

Miles Free III is the PMPA Director of Industry Affairs with over 50 years of experience in the areas of manufacturing, quality and steelmaking. Miles’ podcast is at pmpa.org/podcast.

Email: mfree@pmpa.org — Website: pmpa.org.

RELATED CONTENT

-

Steel Defects Seams on Rolled Steel Products

Learn how to detect and avoid defect seams in rolled steel products.

-

How Do We Fix American Manufacturing?

In America, many have lost sight of the fact that the object of the act of manufacturing is not merely the generation of maximum profit, but instead the creation of value.

-

Subscribe to PMPA Podcasts

"Speaking of Precision" is a podcast from Industry expert Miles Free III, in which he talks about precision machining. All episodes may be found on major platforms.