Cleanliness test results that do not meet requirements can completely stop production if not addressed quickly and can lead to huge costs on the current and future business. The question of comparability is front and center for many quality engineers and quality lab managers. When suppliers use one particular brand of microscope and software, how can they be sure their results are comparable to the results produced by an OEM using a different microscope? The answer is “Standard Analysis” as described by ISO 16232 (or VDA19.1).

This standard has a detailed description of how to apply the proper software settings to detect, measure and categorize most of the particles associated with automotive manufacturing. Here are the three main points that should be confirmed within your microscope software or by checking with your microscope support team:

Featured Content

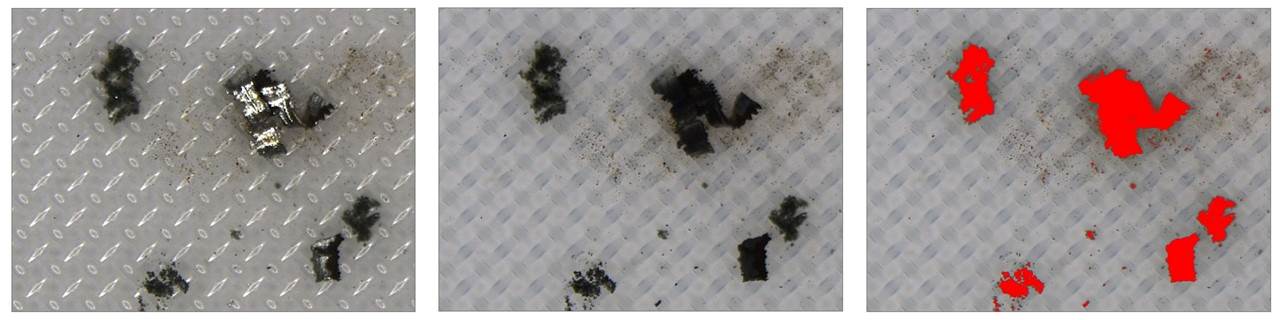

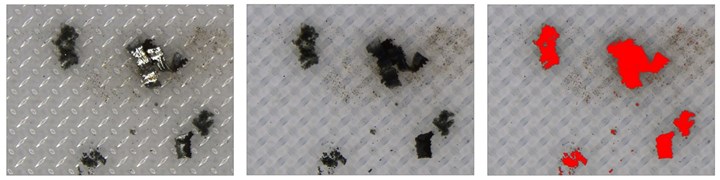

Brightness. The key to accurate particle detection is separating objects (particles) in the image from the background (filter membrane) of the image. A microscope that uses a polarizer must adjust the brightness until the maximum gray value range of the filter background (histogram max) is shifted to 55% +/-5% of the total gray value range. This function should be automated by the software, but, in case the operator must set it manually, the software should clearly show the gray value range so it can be set properly before every test.

Thresholding. After the brightness of the image has been set properly, a detection “threshold” must be set to specify which pixels in the image will be recognized as particles (to be measured) or if the pixel is determined to be from the image background (filter membrane). For microscopes with polarizers, the threshold is set at 70% of the maximum gray value (which was established by the brightness in the step before). Your microscope should automate that step as well, but, if it is manually set by the operator, they must be sure to set it correctly before every filter test. If your microscope does not use a polarizer, this step is even more crucial because there are more manual inputs required by the operator. Incorrectly setting the threshold will result in particles being mistakenly considered as the background or portions of the filter membrane itself being recognized as particles.

Measurement Resolution. Measurement resolution is a setting that will vary from system to system. ISO 16232 standard analysis allows for different microscope designs that will produce different magnifications, as well as different depths of field (focus depth). Rather than referring to magnification (5X, 10X, 20X and so on), ISO 16232 refers to measurement resolution stated in microns/pixel. Regardless of whether you use a material microscope or zoom/stereo microscope, standard analysis requires that software uses at least 10 pixels on the camera to measure any detected particle. The minimum particle size to be measured in standard analysis is 50 microns, so according to the standard, the measurement resolution must be 5 microns/pixel or better (lower number = better resolution) to accurately measure. When comparing particle counts from different systems, the measurement resolution must be considered.

Many other variables are at play and more questions would need to be asked to drill down the differences in your analysis specifically. Other particle properties such as metallic reflection, fiber classification and operator review process are also a common source of reporting differences. Each point should be discussed and agreed upon between suppliers and customers to come to a common understanding of how each other is conducting the cleanliness tests in order to move forward.

Jomesa North America | jomesa.com

About the Author

Peter Feamster is the product manager for Jomesa North America in Troy, Michigan. Feamster has been working in the manufacturing cleaning industry for more than 10 years and specializes in cleanliness analysis.

RELATED CONTENT

-

For Plateau Honing, Consider Ball Style

The ball-style hone is a specialized abrasive tool that is instantly recognizable by its unique appearance. For engineers in the automotive, aerospace, manufacturing and machining industries, this application-engineered hone, characterized by the small, abrasive globules that are permanently mounted to flexible filaments, is a flexible, low-cost tool for sophisticated surfacing, deburring and edge blending.

-

A Race to the Machined Part (Surface) Finish

To improve component finish as well as engine and gearbox performance for its customers, this racing motorcycle rebuild company uses a super-finishing process for gears and related components which is more commonly used for aerospace and jewelry applications.

-

How Eaton Uses Metal 3D Printing

With the ability to address customer needs faster and iterate parts quickly, this metal 3D printing system is now standard within the workflow for both the engineering and toolroom teams.