Shop Combines Automated Grinding and Swiss Turning

Many shops are increasing the scope of their machining capabilities. This Ohio shop has added cylindrical grinding to its 24-hour Swiss-type operations.

Grinding in the Multitasking Mix

While different approaches to multitasking have been around for a while, shops often aren’t aware of many of the advantages these machines offer.

Acoustic Emission Sensing Improves Productivity and Prolongs Grinding Wheel Life

In production of precision metal parts such as automotive or aerospace components, grinding to precise tolerances is of utmost importance.

Thread Grinding with ‘A’ Axis

With several factors propelling a surge in demand for parts with technically complex external and internal threads with large pitches, the need for better accuracy and efficiency has created challenges.

Grinding Advice for Safety

Here are some additional reasons why you should not need gloves when working on grinders and grinding machines.

#basics

Studer Awarded the Gold Metal

At the recently completed Mach show in Birmingham, England, Fritz Studer AG won in the best grinding/finishing equipment category for its new S11 cylindrical grinder.

65 Years in Business

To commemorate its 65th anniversary, Kaiser has opened a second building, co-located with its newly expanded headquarters.

Another Look at Precision Grinding

Often a little ingenuity on the shop floor leads to the most efficient solution. One shop owner developed an effective approach to delivering a burr-free, tight-tolerance part.

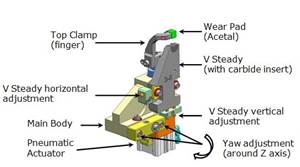

Tool Grind Workholding System Limits Runout

Precision manufacturing requires minimal tool runout, but the amount of runout that is acceptable can be dependent on part tolerances and is often related to the size of the tool.

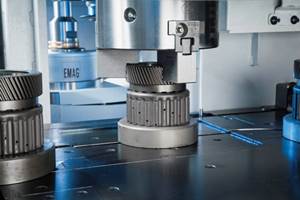

Small Grinding Center Offers Big Productivity Boost

This vertical grinding center for small chucked components with a maximum diameter of 100 mm was developed specifically to meet increasingly higher output levels and shorter cycle times.