Multitasking is More Than Doing Two Things at Once

Combining different metalcutting operations on a single machine platform is helping shops explore better ways to manufacture.

Stretching the Limits with Swiss

This precision component supplier has high expectations when purchasing equipment. Customer requirements are intensifying, and its new technology must keep pace.

Loyalty Bolsters Shop’s Growth

This shop has found its groove with four Ganesh CNC machines that have proven to deliver the performance and quality the company and its customers expect.

Taking a Big Step

This Indiana shop made a leap from manual machining and basic CNC technology to a sophisticated turning cell and has not looked back. It's been a customer driven transition.

Multi-Spindle to Multitasking: A Journey in Productivity

After switching from its outdated multi-spindle machines to multitasking turn-mill centers, this company immediately began reaping the rewards of productivity and throughput increases as well as cost reductions.

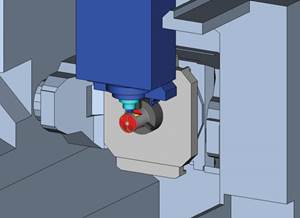

The Y of Multitasking

The Y axis has some primary capabilities that make it extremely efficient and cost effective in multitasking operations.

CAM System Aids with Productivity and Simplifies Complex Parts

In the case of Webber Metal Products, upgrading the CAM system was all it needed in order to increase productivity and simplify complex part production.

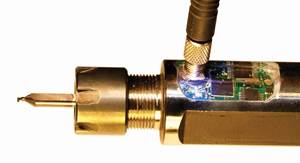

Tool Monitoring for Complex Machining

One of the biggest challenges to tool monitoring on a multitasking machine is coping with simultaneous cutting operations. Caron Engineering (Wells, Maine) designed a system to meet this challenge.

Multitasking Goes Vertical

This article looks at part processing and CNC programming considerations for vertical multitasking applications.

Turning Art into High Precision Parts

Since collaborating with Methods Machine Tools Inc. and implementing its Nakamura-Tome multitasking turning centers, Honor Med Maskiner Corp. (Elgin, IL) has run more efficient processes.