Using Grinding Versus EDM to Finish Form Tools

Finishing carbide inserts using EDM or grinding.

#basics

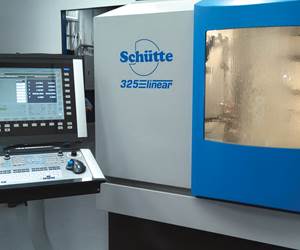

New Centerless Grinder Keeps Shop Moving Forward

When Grind All Inc. realized some of its equipment was out of date, it contacted Total Grinding Solutions about a new centerless grinder in in order to meet AS 9100C regulations.

ID and OD Shoe Grinding for Thin-Walled Workpieces

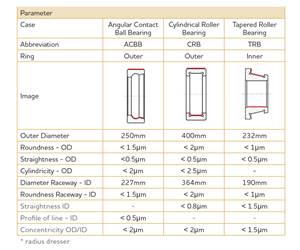

Studer (United Grinding North America) has a solution to the tricky workholding problem of finish grinding close tolerances for roundness and concentricity of thin-walled rings and sleeves or a rolling element such as a bearing raceway.

How Bond Type Affects Production Grinding

To optimize performance, proper grinding wheel selection is imperative. Here's an article that provides an overview of the different abrasive product bond types, the benefits of each, and their typical applications.

#basics

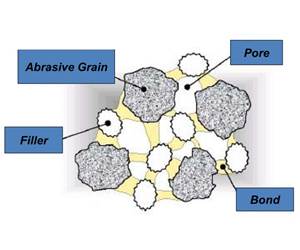

Bond Selection for Production Grinding

Proper grinding wheel selection is essential to ensure that the required part quality, production rate, and overall cost per part is achieved. Although the type of abrasive grain is often a primary driver of wheel selection, the bonding type can also play a key role in optimizing a grinding operation.

Specialized Grinder and Software Speeds Part Production

Once the company implemented a new grinder, it not only saved time during setup, but it improved machine uptime and eliminated the need to purchase additional simulation software.

Manufacturing Efficiently at a Micron Level

Grinding very small-diameter instruments for use in medical procedures is a niche business for this micro-grinding machine manufacturer. The company makes machines that use a variety of grinding techniques to manufacture guidewires for the medical industry.

#micromachining

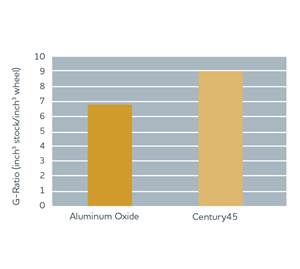

Abrasive Developments for Centerless Grinding

These grinding wheels are designed for greater efficiency by achieving higher levels of stock removal per pass.

Automated Grinding Cell Adds Capacity

Like many shops facing changes in customer demands, Pennsylvania-based American Turned Products (ATP) is making the necessary adjustments and adding operations to continue to compete in the difficult, high volume market. One of those adjustments is the company’s recent installation of an automated centerless grinding cell.

Centerless Grinding Solutions Bring all Processes under One Roof

A supplier of high performance engine components used by major racing teams, including endurance racing, NASCAR and NHRA, SCCA, Le Mans and marine racing, needed to reduce lead times and the cost of grinding its components.