4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

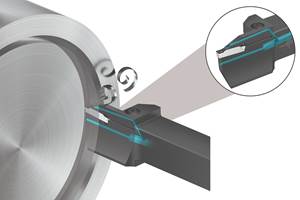

CoroTurn Prime B-Type Inserts Provide All-Directional Turning

The insert is negative and double-sided, offering four cutting edges to increase productivity and tool life.

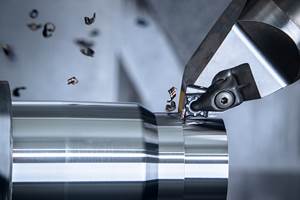

Walter Axial Grooving System Features Two Cutting Edges

The company says a key to the system’s success is the Walter Cut G1111-P holder and AF5 axial grooving chipbreaker system, which are said to deliver strength, reliability, optimum surfaces and high cost efficiency for axial grooving.

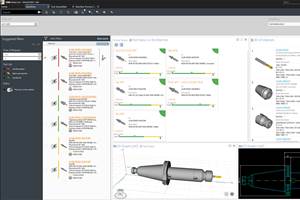

TDM Tool Management Systems for Production Efficiencies

The company’s latest data management support for customers includes new data services and a cloud-based solution.

#Industry40

Tips to Make CNC Machining Tool Failure Predictable

Accurate prediction of tool life is key to establishing a controlled, repeatable and reliable CNC machining process.

#techbrief

Greenleaf-360 Solid Carbide End Mills for Increased Tool Life, Productivity

The submicron grade is said to provide great toughness and wear resistance that offers customers one grade that can be applied in many different applications.

Ceratizit’s Dragonskin Multilayer Tool Coating for Improved Tool Life

The tool coating consists of nanometer-thin layers which are created by combining different properties of different chemical compositions to achieve the desired results.

Air-Actuated Back-Spotfacing is Now an Option

A coolant-actuated, back-spotfacing tool design is now available in an air-actuated version for machines that don’t offer through-tool coolant delivery or parts that can’t be machined using coolant.

#techbrief

EWA Fine Boring Head for Fully Automatic Closed-Loop Operations

IMTS 2022: Big Kaiser’s EWA Automatic Fine Boring System is said to perform closed-loop boring operations without a human operator, eliminating the need to stop the spindle to manually adjust the boring tool and resulting in reduced cost, improved accuracy and minimized scrap.

Allied Insert for Cutting Stainless Steel, HRSA Materials

Allied Machine and Engineering’s M geometry T-A Pro insert has been engineered to provide a combination of longer tool life, good penetration rates and process reliability for cutting stainless and heat-resistant super alloy materials.