MATERIALS

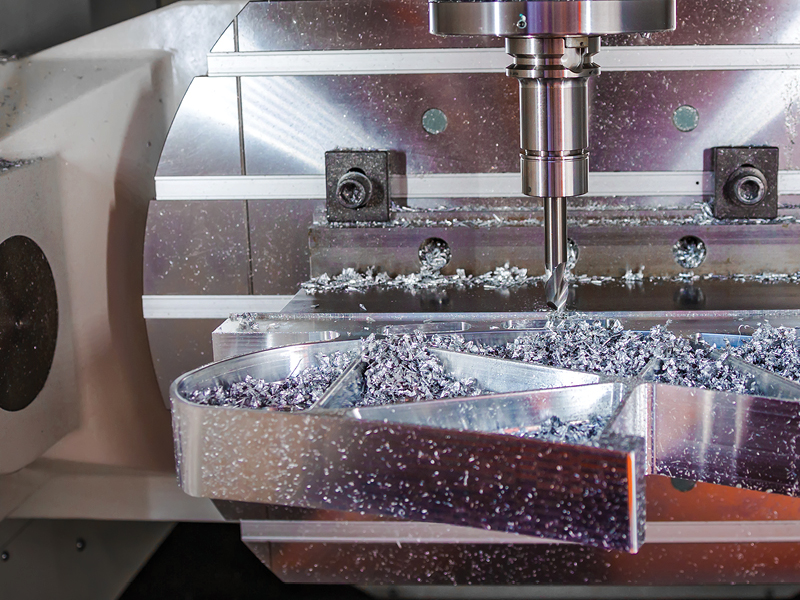

Production machine shops often must source various types of material including aluminum, brass, steel, stainless steel, titanium, high-temperature alloys and plastics in bar, blank or plate forms.

Narrow by Materials Product Category

FAQ: Materials

What stainless is easiest to machine?

Ugitech’s controlled oxide, high machinability stainless steels are available in the common stainless grades. This technology, along with consistent manufacturing and combined with technologies such as SMQ (Swiss Machine Quality—a precision cold drawn bar with Swiss tolerances and superior bar straightness), is resulting in drastically reducing machining costs and remaining cost effective.

(Source: Making Stainless More Machinable)

How do I straighten bar stock for a bar feeder?

One of the most common issues affecting bar feeder performance is wear and tear on the bar feeder liner or collet caused by inaccurate alignment between the bar feeder and the lathe. Typically caused by vibration during production or accidental bumping of the bar feeder, misaligned bar feeders lead to more frequent production stops and time-consuming bar feeder maintenance.

Regularly scheduled alignment and careful attention to incidents that may influence the current alignment can help to minimize more significant downtime. But conventional alignment methods, such as the use of tight wire or line, or even simply eyeballing the setup, can often be time consuming and inaccurate. High-end laser alignment systems can be costly and typically require a significant amount of training.

The L56SS bar feeder alignment system from Laser Tools Company Inc. was designed as an affordable, simple system to enable shops to quickly and accurately check bar feeder alignment. The system uses a straight beam of laser light and two targets to center and position the bar feeder carriage to the right height for supplying barstock material to the lathe spindle. The alignment of the center of the bar to the center of the spindle is critical because the barstock is automatically pushed or fed into the lathe’s spindle in order to begin the machining process. Proper alignment reduces wear on spindle liners and guide bushings, ensures correct remnant release, assists in end of bar management, and saves valuable setup time.

(Source: Laser Device Helps to Align Bar Feeders)

Get Listed!

Thousands of people visit this Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.