CNC Transfer Machine Boasts Short-Run Flexibility

More and more manufacturers are requiring their precision machined parts suppliers to enter into just-in-time (JIT) relationships in which smaller order quantities are supplied at more frequent intervals.

Closing The CNC Price Gap

Applying CNC technology to the manufacturing of precision parts is generally accepted as a premium that one must pay for the advantages over conventional actuation systems. Increasingly, however, the gap is narrowing as economies of scale for producing CNC equipped machine tools are incorporated in the unit price of a given machine. In other words, spreading the costs of manufacturing over a larger base of installations will reduce the price of each machine.

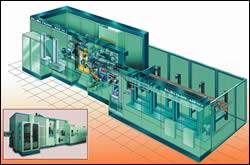

Making Transfer Machines More Flexible

Are your lot sizes too big for machining centers but too small for dedicated transfer machines? Here's a solution.

Machine Both Shaft Ends Simultaneously

If your production operations include shaft work, you will want to know about this rotary transfer machine, which produces up to 30 shafts per minute by machining both shaft ends simultaneously.

A Diet Of High Volumes, Long Runs

Suggest a strategy of high volumes and very long runs, and many screw machine houses grow anxious. Add that the high volumes are for automotive customers, and the anxious soon become squeamish—except in the case of this supplier. It thrives on the volumes and chases the long runs.

Filling The Gap Between Single- And Multi-Spindle Machines

What do multi-spindle screw machine users need/want in their next machines? Five features are mentioned most frequently by customers: flexibility; easy changeover from one job to the next; ability to use readily available off-the-shelf tooling; greater accuracy and consistency; and ease of operation and maintenance.

Style And Substance

At the Simodec show in France, Wirth & Gruffat (Argonay, France) introduced a new machine called Transturn TT-312. It is designed to combine the advantages of multi-spindle screw machines and rotary transfer technology. The company calls it a manufacturing cell.

Vertical Indexing Machine Produces Fittings With Greater Accuracy

This high production indexing machine is said to be able to produce a family of tees and elbows from a variety of materials with holes ranging in size up to ¾ inch NPT in mild steel.

A Formula For Success: Refocus, Size Down, Add Value

This cold former uses high production rotary transfer machines for value added machining. It's a very successful one/two combination.

Boosting Part-making Efficiency With Rotary Transfer

This rotary transfer machine enabled this shop to increase efficiency and cut the part price by 20 percent.

.jpg;maxWidth=300;quality=70)