Precision Machining Technology Review November 2021: Workholding

Production Machining’s workholding showcase includes SMW Autoblok, Forkhardt, Mate Precision Technologies, Norgren, Jergens and Platinum Tooling.

CNC Collet Chucks, Modified Standard Collets for Unique Part Geometries

The setup with Zagar Inc.’s 22c CNC collet chucks and its standard collets is designed to help ensure machining performance while providing very low runout as well as quick changeover to keep machine uptime high.

Tecnicrafts Collets, Guide Bushings for Swiss Turning Applications

Platinum Tooling Technologies offers Tecnicrafts Industries’ collets and guide bushings for Swiss-type CNC Lathes.

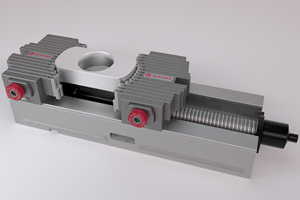

Jergen Dovetail Vises Offer Modular Quick-Change Options

These dovetail vises are said to offer secure clamping with minimal material, and are well suited for parts with multiple operations and larger metal removal.

Adaptix Soft Jaw Provides One-Size-Fits-All Workholding Process

Adaptable soft jaw is designed to streamline CNC machining process and provide a one-size-fits-all way to enhance workholding efficiency.

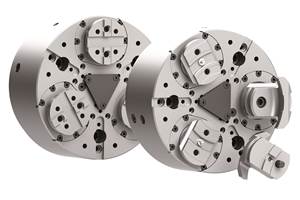

Forkhardt’s FNC+ Quick Jaw Change Power Chuck Offers Manufacturing Versatility

A reduced chuck body weight results in having less mass on the spindle and enables machine manufacturers to permit/machine a higher workpiece weight and attain higher rpms.

SMW BP Chuck Made for Harsh Machining Environments

The BP features a large through-hole that enables flexibility for virtually any application where a standard chuck is used.

Precision Machining Technology Review May 2021: Workholding

Production Machining’s May Product Showcase includes new workholding equipment from Hainbuch, SMW Autoblok, Schunk, Northfield Precision and Ringspann Corp.

TX Series Pull-Down Chucks Have Constant Clamp Force at Higher Speeds, Feeds

SMW Autoblok’s 3-jaw pull-down chucks are fully sealed, featuring high accuracy and heavy-duty gripping for metal cutting applications.

Custom Tooling, Workholding Help Whip Rotors Into Shape

Whipple Superchargers uses unique form tools and dead-length-collet workholding for its B-axis turn-mill enabling it to create more accurate rotors for its brand of engine power-adders.