Video Tech Brief: Bar Feeder Technology Optimized for Swiss-Types

This bar feeder design is said to offer high guidance quality with minimum vibration and noise development for sliding-headstock machines.

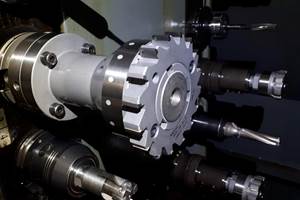

Lyndex-Nikken Toolholders Offer Stable, Versatile Machining

Polygonal shank toolholders provide a rigid connection between the tool and machine — ideal for all processes both in turning and milling.

Precision Machining Technology Review August 2023: Tooling

Production Machining’s August 2023 technology showcase includes some of the latest tooling technology from Monaghan Tooling Group, Big Daishowa, Kennametal, Tungaloy-NTK America Inc. and Accutek.

Dillon Workpiece Stops Reduce Setup Time

The workpiece stops enable short parts to be set above the jaws, providing clearance.

Tooling Considerations for Parting Off, Grooving

Geometry, coatings and tool holders all play a big role in the effectiveness of parting off and grooving operations on CNC turning centers.

#techbrief

Tungaloy-NTK PCD Grade Offers Optimal Dimensional Accuracy

The DX200 is an effective tool for machining application-specific components that demand high levels of material purity, such as metal medical implants and sputtering targets for semiconductor applications.

Tips for Choosing the Right Toolholder for High-Speed Machining

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

#techbrief

Big Daishowa Toolholder Increases Precision for Lathes

The Big Capto C3 series provides higher rigidity to minimize vibrations and movement during cutting, improving accuracy and efficiency.

Threaded Lathe Sleeves Maximize Pressure, Coolant Flow

The sleeves are well suited for job shops that are using aging lathes, and are designed for use on machines that do not have the capability to run through-the-turret coolant.

Kennametal Drill Fix PRO Offers Extended Application Range

The Drill Fix PRO is designed for extended tool life and smooth drilling at high metal removal rates, with outboard inserts that feature a wiper geometry for smoother surface finishes and larger coolant channels for high-volume flow.