Big Daishowa Enhances Boring Tools With Vibration Damping

Smart Damper technology shortens the distance from the damping mechanism to the cutting edge, which is the source of vibration.

Tungaloy Grooving Toolholders Provide Stable Turning

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

Precision Machining Technology Review October 2023

Production Machining’s October 2023 technology showcase includes some of the latest technology from Tungaloy-NTK America Inc., Renishaw, Walter USA, Seco Tools and Haimer USA.

#Industry40

Seco Tooling Lineup Promotes Optimized Part Processing

The company’s expanded tooling lineup is aimed at applications ranging from general ISO turning to high-volume hard turning and deep-hole drilling.

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

#horizontal-and-vertical-lathes

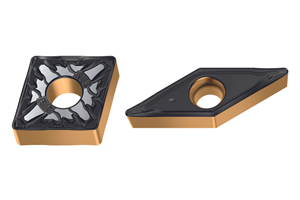

Walter Turning Grades Reduce Machining Times

The WKP01G and WPP05G grades are ideal for continuous cutting and occasional interrupted cuts in high-tensile materials.

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Tungaloy-NTK PCD Grade Offers Optimal Dimensional Accuracy

The DX200 is an effective tool for machining application-specific components that demand high levels of material purity, such as metal medical implants and sputtering targets for semiconductor applications.

Tooling Considerations for Parting Off, Grooving

Geometry, coatings and tool holders all play a big role in the effectiveness of parting off and grooving operations on CNC turning centers.

#techbrief

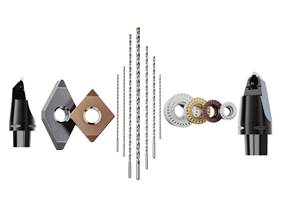

Kennametal Drill Fix PRO Offers Extended Application Range

The Drill Fix PRO is designed for extended tool life and smooth drilling at high metal removal rates, with outboard inserts that feature a wiper geometry for smoother surface finishes and larger coolant channels for high-volume flow.