Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

#micromachining

Walter Indexable Drill Inserts Provide High Wear Resistance

The WNN15 drilling grade features a hard substrate, which provides high cutting-edge strength and sharpness on indexable inserts.

SMW Autoblok Vise System Provides Omnidirectional Clamping

The Plus5 V5 Zero Point Vise system interfaces with all industry-standard products using 52 mm or 96 mm pin spacing, enabling it to readily become part of existing workholding systems.

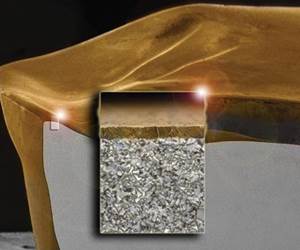

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Precision Machining Technology Review: January 2024

Production Machining’s January 2024 technology showcase includes some of the latest technology from Monaghan Tooling Group, Okuma America, Tungaloy, Cortec Corp., Fixtureworks and T.J Davies Co. Inc.

Tungaloy Fine-Boring System Increases Machine Utilization

The latest KKH cartridge modules for the SwissBore digital fine boring tool system is designed to provide maximum machine utilizations with minimum measuring, setup and tool changing time.

Bar Feeder Designed with Swiss-Types in Mind

New technology enables this bar feeder to fully support the bar pusher and stock from inside the unit all the way to the spindle of a sliding headstock lathe.

#techbrief

Sandvik Coromant Grooving Tool Provides Stable Performance

The CoroCut 2 system features an improved clamping finger design, which offers a higher clamping force and better side stability.

Monaghan Compensation Chucks Convert Standard ER Holders

Diatool ER Hydraulic Compensation Chucks enable users to convert standard ER holders to a repeatable, steerable hydraulic chuck for more precise machining.

Lyndex-Nikken Collet Chuck Increases Gripping Force

SK collet chucks enables for access to tight spaces and provides better clearance, making it ideal for machining complex parts.