Mazak Integrex i-100HS Multitasking Machine for Complex Part Applications

It is said the machine combines the abilities of a high-powered turning center with a full-function machining center to produce small- and medium-sized workpieces in single setups.

Index MS32-6 Multi-Spindle Automatic Lathe Features Flexible Tool Slide

Six-spindle machine with a flexible tool slide platform is said to easily handle a wide variety of complex parts.

How Fast Can You Change Over a Multi-Spindle?

Today’s CNC multi-spindles feature design elements that enable these high-production machine tools to be effective for lower-volume jobs that require more frequent setups.

Customizable CNC Machine, Automation Solutions

IMTS 2022: BA W08-12 is designed for machining large workpieces made of aluminum and other nonferrous materials.

#imts #Industry40

Can a Job Shop Benefit From a CNC Multi-Spindle? This One Does.

Although CNC multi-spindle machines are often dedicated to running one part or family of like parts, this Wisconsin job shop has found a way to make 20,000 parts per run its sweet spot for that equipment to better serve multiple customers.

#workforcedevelopment

How Advancements in CNC Multi-Spindles Can Put You Ahead of Current Trends

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

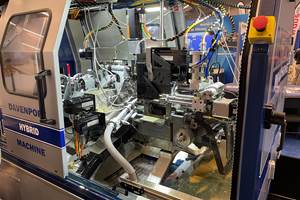

What’s Still Cam-Driven and Why?

Combining select cam-driven functions with CNC technology for this multi-spindle platform is said to help reduce machine cost while retaining high machining speed, precision and production.

#techbrief

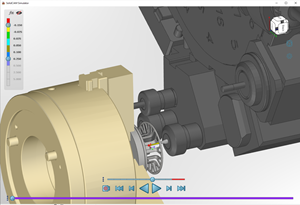

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

#basics #horizontal-and-vertical-lathes

SW’s Single-Table Machines Designed for Machining Large Parts

SW’s BA W08-11 and BA W08-21 can be automated with a variety of solutions, including TopRob which facilitates the loading and unloading of large and heavy workpieces with the aid of robots on platforms or gantries above the machine.

Production Turning to CNC

The precision production turning industry is trending away from cam-actuated automatics. While limited legacy machine capability and skilled labor resources are two large factors, economics is the primary driver.